I just received a Ryobi 18v 320psi cordless power washer. Maybe worth a thought if you don't mind crouching down.As a side note I saw that the cooling fins on my transmission housing are caked in dried on mud, I guess I need to find a place where I can lift up my Grenadier and power wash the mud off, anyone happen to know such a place in the Phoenix Area?

The Grenadier Forum

Register a free account today to become a member! Once signed in, you'll be able to contribute to the community by adding your own topics, posts, and connect with other members through your own private inbox! INEOS Agents, Dealers or Commercial vendors please contact admin@theineosforum.com for a commercial account.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Don’t forget there is a horizontal angle imparted on each joint (not just a vertical angle) as none of the major components are in a perfectly straight line down the length of the vehicle. Horizontal angles also contribute to the overall workload each CV joint has to do when spinning and transferring torque. Not something folks think about when lifting their vehicles as the more obvious concern is the vertical angle.This made me curious enough to attempt to measure the angles on my stock drivetrain with nonstock springs (Eibach 2.5 lift). I found it difficult to measure the angles and the numbers were much lower than I would have guessed by just looking at the angles. The numbers I measured below are the most conservative measurements I made (i.e. highest angle I measured) at each joint. For each measurement I attempted to measure both sides of the axle in an attempt to get a flat surface as a guide (i.e. the diff housing).

If my measurements are even close to correct, then we should easily be within the 15 degree allowance of the Teraflex unit. I wonder what the tolerances are for the stock unit?

I'm not sure if someone else who is more agile and perhaps has better tools to measure the angles can double check my measurements?

Here is what I found:

_____________________

Front driveshaft where it connects to the front diff:

About 7 degrees

[Edit note: This is simply a photo so I would know what measurement I took, it is not me actually doing the measuring. When I had the protractor aligned to take the measurements it required both hands and at that point I had the center of the protractor alighted about even with where those screw heads meet the metal housing. I didn't have a third hand to help take a photo at that point.]

______________________

Front driveshaft where it connects to the center diff, about 6.5 degrees:

(sorry for the crappy photo)

__________________

Rear driveshaft where it connects to the center diff, about 3.5 degrees:

_______________

Rear driveshaft where it connects to the rear diff, about degrees also about 3.5 degrees:

______________

As a side note I saw that the cooling fins on my transmission housing are caked in dried on mud, I guess I need to find a place where I can lift up my Grenadier and power wash the mud off, anyone happen to know such a place in the Phoenix Area? This was a very common service for car washes when I lived in Saudi.

It would be interesting to strap a GoPro on and watch what happens when flexed outDon’t forget there is a horizontal angle imparted on each joint (not just a vertical angle) as none of the major components are in a perfectly straight line down the length of the vehicle. Horizontal angles also contribute to the overall workload each CV joint has to do when spinning and transferring torque. Not something folks think about when lifting their vehicles as the more obvious concern is the vertical angle.

285/70/17 KM3's here. No rub.So a 275/70/17 or what?

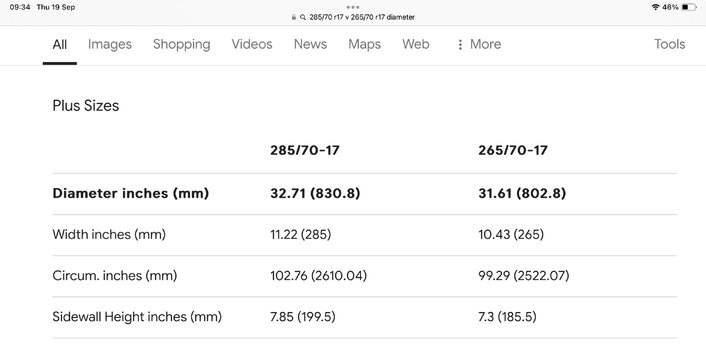

Ok - that’s helpful. I guess that’s the plan for now, then, if people want a little more clearance without the risk of a drive shaft failure and warranty issues. It’s probably also worth noting that if you go to 285/70/17, you’re only picking up 1.1” of total tire diameter - just over 1/2” of additional clearance.285/70/17 KM3's here. No rub.

Are you running those on stock rims or did you get something with some offset?

Last edited:

Stock 17" steels. I bought a spare set off of spjnr on here. Kept my K02's for the alps. I do very much like the look of the bigger tyre and it's necessary for me to have m/t here as an awful lot of clay down here in Sussex and the K02's just slick up.Ok - that’s helpful. I guess that’s the plan for now, then, if people want a little more clearance without the risk of a drive shaft failure and warranty issues. It’s probably also worth noting that if you go to 285/70/17, you’re only picking up 1.1” of total tire diameter - just over 1/2” of additional clearance.

Are you running those on stock rims or did you get something with some offset?

I've been considering going to this tyre size but on paper at 32.7" diameter the 285/70R17's are only +1.1" compared to the 31.6" diameter of the stock 265/70R17 tyres. As this only equates to a 0.55" lift (because the other half of the tyre is above the axle) I can't justify the ~£1,800 price tag for a set of 5 new tyres in my head. A true 34" tyre would be in the realm of 285/75R17 but numerous searches online have been fruitless - no one seems to offer a quality tyre at any size bigger than 285/70R17 in the UK. If anyone has managed to source a decent 34" tyre option in the UK I'd be keen to hear about it.285/70/17 KM3's here. No rub.

In the meantime it seems to me that adjusting the suspension components would be the easier option for increased ride height, if it wasn't for the drive shaft concerns. I think I'm going to sit this one out on the stock set up for a year and see what the after-market providers develop and the early adopters fail to break

Hmm - probably better for the wheels/tires thread instead of driveshaft - but I was less than thrilled by the K02’s in snow/ice (had a couple of blizzards after I picked up the Grenadier this spring), so ordered Blizzak LT’s for when it gets really bad. Won’t put them on until November so don’t know how much it will improve performance.Stock 17" steels. I bought a spare set off of spjnr on here. Kept my K02's for the alps. I do very much like the look of the bigger tyre and it's necessary for me to have m/t here as an awful lot of clay down here in Sussex and the K02's just slick up.

It will be interesting to see when reports come out on KO3 in snow and ice. They seem to have more sipes from the reviews I saw, making hopefully for a more compliant and flexible tread on ice and in snow. We shall see. Certainly they will never match a proper winter tire.Hmm - probably better for the wheels/tires thread instead of driveshaft - but I was less than thrilled by the K02’s in snow/ice (had a couple of blizzards after I picked up the Grenadier this spring), so ordered Blizzak LT’s for when it gets really bad. Won’t put them on until November so don’t know how much it will improve performance.

Last edited:

There's probably a category for this on pornhubIt would be interesting to strap a GoPro on and watch what happens when flexed out

I've been considering going to this tyre size but on paper at 32.7" diameter the 285/70R17's are only +1.1" compared to the 31.6" diameter of the stock 265/70R17 tyres. As this only equates to a 0.55" lift (because the other half of the tyre is above the axle) I can't justify the ~£1,800 price tag for a set of 5 new tyres in my head. A true 34" tyre would be in the realm of 285/75R17 but numerous searches online have been fruitless - no one seems to offer a quality tyre at any size bigger than 285/70R17 in the UK. If anyone has managed to source a decent 34" tyre option in the UK I'd be keen to hear about it.

In the meantime it seems to me that adjusting the suspension components would be the easier option for increased ride height, if it wasn't for the drive shaft concerns. I think I'm going to sit this one out on the stock set up for a year and see what the after-market providers develop and the early adopters fail to break

I seem to recall that some people were able to run the pizza cutters 255/85/17's without a lift and with no rub. That would be a 34.07" diameter tire.

Can't get them in the UK sadlyI seem to recall that some people were able to run the pizza cutters 255/85/17's without a lift and with no rub. That would be a 34.07" diameter tire.

just noticed, Eibach USA has added the following statement to their 2.5 lift spring description.

Tested with factory dampers. Recommended to pair with Eibach Pro-Truck Reservoir Shocks. Damage could occur to factory drive shaft with change in ride height. Consult instruction manual for proper installation.

Tested with factory dampers. Recommended to pair with Eibach Pro-Truck Reservoir Shocks. Damage could occur to factory drive shaft with change in ride height. Consult instruction manual for proper installation.

A real vote of confidence when a manufacturer states out in the open their own plausible deniability. Do we need anymore evidence that big lifts on a Grenadier should be avoided at this stage until more engineering is done to the vehicle?just noticed, Eibach USA has added the following statement to their 2.5 lift spring description.

Tested with factory dampers. Recommended to pair with Eibach Pro-Truck Reservoir Shocks. Damage could occur to factory drive shaft with change in ride height. Consult instruction manual for proper installation.

I just double checked. The statement is in the description for ALL of their Grenadier lift springs.

one more, A search on their website indicates the referenced shocks are not available for the Grenadier!

Standard boiler plate for any aftermarket suspension. Nothing surprising about the disclaimer.

wasn't there until this week, otherwise I would have purchased the shocks when I got the springs in April or either not purchased them.Standard boiler plate for any aftermarket suspension. Nothing surprising about the disclaimer.

No shocks, either OEM, Eibach or from another aftermarket manufacturer will do anything to change the issue regarding the drive shaft. And if those shocks are longer than the OEM spec then they will only exacerbate the issue.

The bottom line is that suspension modifications on any vehicle, Ineos, Jeep, Toyota or otherwise involve compromises to reliability and durability regardless of whether this happens to be called out in a fine print disclaimer.

The bottom line is that suspension modifications on any vehicle, Ineos, Jeep, Toyota or otherwise involve compromises to reliability and durability regardless of whether this happens to be called out in a fine print disclaimer.

Similar threads

- Replies

- 104

- Views

- 4K

- Replies

- 4

- Views

- 163

- Replies

- 23

- Views

- 1K