If the bearings a torqued that implies that there is no preload require to be set and the bearing are like some wheel bearings on trucks, so no grease repacking. Guessing for the full floating the flange set up has to go over the wheel studs using an o'ring as a seal, shown by the grove around the center, this makes the wheel nut tension more critical as the wheel lugs/studs are essentially what is holding the axle in position and providing the holding force for the axle to drive the car. It is a bit different to the full floating set ups usually seen in Australia on trucks, Dana and Land Cruisers. Looking at the center of the hub it has the traditional semi floating axle look. The wheel bearing socket will be a diy tool on the list (to loan to independent mechanic if the need arises) and hopefully the hubs and bearings don't need lots of force with a puller to be removed making a field repair easier. Ineos really needs to release service manuals with general access for those workshops that will repair these when people are travelling.Rear bearings are sealed and require a torque of 600Nm according to the engineer at the Tech Talk in Brisbane several weeks ago...

The Grenadier Forum

Register a free account today to become a member! Once signed in, you'll be able to contribute to the community by adding your own topics, posts, and connect with other members through your own private inbox! INEOS Agents, Dealers or Commercial vendors please contact admin@theineosforum.com for a commercial account.

Steering and Poor Stability

- Thread starter bobbyray1969

- Start date

-

- Tags

- steering

It is a design decision. In most older trucks, the rear axle pinion is pointed slightly up, towards the transfer case. In the Grenadier, the double-CV-jointed driveshafts don't require that.Isn't 0 not quite normal at solid rear? Otherwise the drive shafts and the flange will be tilt (correct term? I mean not in line).

AWo

The dealer shows pretty much 0 or straight on the rears.

If I can figure out how to get photos up here I'll show you how beefy the FULL FLOATER! Rae axle shafts are!

I just figured it out. Duh...

Do you have more info on the axle? Did you count the splines by chance? Can you show more of how the axle is taken apart. Ineos said that these were supposed to be semi floating from my memory.

If the bearings a torqued that implies that there is no preload require to be set and the bearing are like some wheel bearings on trucks, so no grease repacking. Guessing for the full floating the flange set up has to go over the wheel studs using an o'ring as a seal, shown by the grove around the center, this makes the wheel nut tension more critical as the wheel lugs/studs are essentially what is holding the axle in position and providing the holding force for the axle to drive the car. It is a bit different to the full floating set ups usually seen in Australia on trucks, Dana and Land Cruisers. Looking at the center of the hub it has the traditional semi floating axle look.

From the previous @CORE Ineos pictures the front wheel bearings appear to be a typical sealed unit bearing. Yes, technically they are full floating but not in the way most are used to. There generally isn't a spindle as the bearing is pressed into the knuckle in a manner akin to tapered ball joints - i.e. - with a friction fit. Bolts/nuts are commonly used to maintain the press fit but do not support the weight of the vehicle. I was told at the Seattle event that the front wheel bearings were indeed pressed into the knuckles by the manufacturer. Without the wide inner/outer bearing spacing of a traditional spindle there can be a much lower safe weight and tire size limit when using unit bearings. I'd assume Ineos stepped up the bearing size to meet any realistic load increases that might be imposed by the end user. You will need to remove the unit bearing from the knuckle to change or service the inner axle shaft as there's no way to get the double cardan u-joints out of the axle housing. Axle seals are just outboard of the carrier bearings as the sealed unit wheel bearing doesn't need any additional lubrication and are usually non-serviceable. There is no oil or grease in the axle housing outboard of the inner seals in contrast to sealed front axle assemblies folks here are used to with older Land Rovers, Land Cruisers, etc. The wheel studs are integral and often not removable.

The rear wheel bearing in the pictures also appear to be sealed unit style pieces that are pressed in but the torquing of some kind of fastener to the phenomenal 442 ft-lbs (600nm) kind of makes me think there's a short spindle or boss on the end of the housing. They do not appear to be similar to any semi-floating set-up I am familiar with but maybe they are? Looking at the shaft you can see that it necks down after the splines to allow removal without disturbing the bearing(s) or any flanges which appear to all be part of a single unit. That says full floating by definition.

In theory I'm okay with unit bearings. You can't spin a bearing and then gall the underlying spindle (which ruins entire rear axle housings) or an expensive hub. The hub/bearing/spindle is all one piece and is usually interchangeable side to side. You'll just need a single spare per end in the box but 600Nm/442ft-lbs is a lot of force to be mustering on the trail somewhere.

Last edited:

It is a design decision. In most older trucks, the rear axle pinion is pointed slightly up, towards the transfer case. In the Grenadier, the double-CV-jointed driveshafts don't require that.

In older 4X4s the upward tilt of the rear pinion is usually the result of badly worn leaf springs. The wear occurs because power applied to the rear axle tries to flip the vehicle over on it's back. We call this "poppin' a wheelie". Eventually the front end of the leafs begin to curve in the opposite direction causing the pinion shaft to rotate upward. The solution is to fit caster wedges between the axle housing and the spring pack to rotate the pinion back down and come back into spec. It happens with coil sprung vehicles as well but to a lesser degree and has different remedies but the science is the same.

In theory the output shaft of the transfer case and the differential pinion shaft should match exactly ( @AWo ). Do to the opposite differential rotational forces between front and rear driven axle assemblies most manufacturers favor correct geometry with the rear driveshaft and components. Part time 4X4s benefit the most from this approach and are often fitted with DC joints at the front output shaft for simplicity but I haven't found such approaches necessary at the moderate speeds traditionally driven in 4 Hi or with a locked center diff in full time vhicles. If front and rear differential pinion shafts are aligned with the operational angles of the transmission/transfer case outputs all is well providing suspension components are in good repair.

With the extreme lifts, high horsepower, and high speeds now driven not only in competition but also by the Sunday Offroader, doing what's known as a "cut-and-turn" to point diff pinions straight at the t-case where a DC joint is used has become a common approach to lessening driveline vibration and increasing universal joint life - for a while.

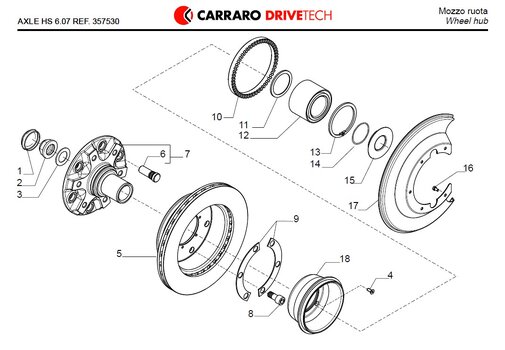

1. Carraro HS6.07 Axle front wheel bearing assembly. Vari Brake upgrade. 2. Ineos Grenadier Carraro front axle

4. Rear FF hub Carraro Iveco 4x4. Photos from 4x4 Iveco Daily FB pages.

I refer back to SCAM built 4x4 Iveco Daily as the closest axle comparison, it has the larger model Carraro front and rear full floating axles then the Grenadier but essentially share the identical design (12 bolt cover not 9 bolt using Chevy terms). Both front and rear wheel bearings need a puller to remove the wheel hubs and a special factory tool or a custom made fixture to remove and replace the front wheel bearing with out damaging the housing. Some mechanics have reported using between 10 to 20t and some more to remove the front wheel bearing from the knuckle with their custom made jigs used in a workshop press. From what I have been told by a few who have done the job and some research the wheel bearing is pressed in from the back of the steering knuckle on to a shoulder while hub presses in from the front and is held into the bearing with the drive axle. I expect the same for the Grenadier.

When the Daily 4x4 has experienced major wheel bearing failure most have been towed to a workshop for repair while others have been successful in replacing wheel bearings as preventative maintenance with a well equipped home workshop. This has been documented in various peoples travel pages and vlogs. The rear full floating hub will require to be assembled with the bearing if it is to be carried as a spare. As a field repair with limited tooling, the wheel bearings on Grenadier and Quartermaster are going to be a job where out of the box MacGyver type thinking will be required and will be a relatively difficult task for the inexperienced DIYer to complete.

Is there any data on the mean time/distance between failure for the 4x4 Daily wheel bearings?View attachment 7852148View attachment 7852151

1. Carraro HS6.07 Axle front wheel bearing assembly. Vari Brake upgrade. 2. Ineos Grenadier Carraro front axle

View attachment 7852123View attachment 7852147

4. Rear FF hub Carraro Iveco 4x4. Photos from 4x4 Iveco Daily FB pages.

I refer back to SCAM built 4x4 Iveco Daily as the closest axle comparison, it has the larger model Carraro front and rear full floating axles then the Grenadier but essentially share the identical design (12 bolt cover not 9 bolt using Chevy terms). Both front and rear wheel bearings need a puller to remove the wheel hubs and a special factory tool or a custom made fixture to remove and replace the front wheel bearing with out damaging the housing. Some mechanics have reported using between 10 to 20t and some more to remove the front wheel bearing from the knuckle with their custom made jigs used in a workshop press. From what I have been told by a few who have done the job and some research the wheel bearing is pressed in from the back of the steering knuckle on to a shoulder while hub presses in from the front and is held into the bearing with the drive axle. I expect the same for the Grenadier.

When the Daily 4x4 has experienced major wheel bearing failure most have been towed to a workshop for repair while others have been successful in replacing wheel bearings as preventative maintenance with a well equipped home workshop. This has been documented in various peoples travel pages and vlogs. The rear full floating hub will require to be assembled with the bearing if it is to be carried as a spare. As a field repair with limited tooling, the wheel bearings on Grenadier and Quartermaster are going to be a job where out of the box MacGyver type thinking will be required and will be a relatively difficult task for the inexperienced DIYer to complete.

Last edited:

From what I have been told in the Daily can vary and is totally dependent on operating conditions, some mine vehicles before 100000km. The 4x4 Daily factory front brakes are a bit undersized for heavy towing and were known to over heat in some circumstances considerably reducing the life of front wheel bearings. For most every day users I would expect the Grenadier's wheel bearings to last to 200000km+ with little issues but they need to be checked for movement every service. A lot of water crossings, like any wheel bearing, will reduce the life because moisture always eventually finds its way into bearings when they're hot then suddenly cooled.Is there any data on the mean time between failure for the 4x4 Daily?

Not necessarily in a vehicle with a driveshaft with 2 CV joints - as it is in the Grenadier.In theory the output shaft of the transfer case and the differential pinion shaft should match exactly

I just got through all 11 pages of this thread. Thanks to everyone that contributed so far. I'm here to report I have the same issue. I picked up my Grenadier from SoCal and drove it 6+ hours to NorCal and the handling was all over the place. It was definitely a sketchy drive especially at speeds around 75mph+ and on curves. It was like I had to super focus on driving and keep both hands on the wheel at all times.

For folks that have this issue "corrected": was it a caster adjustment that ultimately fixed it for you?

For folks that have this issue "corrected": was it a caster adjustment that ultimately fixed it for you?

I think people are getting 90% of their relief from two things.I just got through all 11 pages of this thread. Thanks to everyone that contributed so far. I'm here to report I have the same issue. I picked up my Grenadier from SoCal and drove it 6+ hours to NorCal and the handling was all over the place. It was definitely a sketchy drive especially at speeds around 75mph+ and on curves. It was like I had to super focus on driving and keep both hands on the wheel at all times.

For folks that have this issue "corrected": was it a caster adjustment that ultimately fixed it for you?

Tire air pressure with average vehicle cargo load, and

Hours/miles behind the wheel.

I've not detected any recent reports of steering geometry settings being far off factory specification on recent deliveries.

I think people are getting 90% of their relief from two things.

Tire air pressure with average vehicle cargo load, and

Hours/miles behind the wheel.

I've not detected any recent reports of steering geometry settings being far off factory specification on recent deliveries.

I'm one of those. I am down to 38/39 fr/rr and about 1750 miles and I can handle it just fine.

Thanks bbq4133. And did you have the highway handling issues I mentioned initially and resolved them solely by adjusting your tire pressures down?I'm one of those. I am down to 38/39 fr/rr and about 1750 miles and I can handle it just fine.

Thanks bbq4133. And did you have the highway handling issues I mentioned initially and resolved them solely by adjusting your tire pressures down?

I was very...nervous...on the highway initially. Once I figured out the tire pressures that worked with my load and also drove it a bunch I am no longer nervous.

- Local time

- 10:03 PM

- Joined

- Sep 30, 2021

- Messages

- 424

I really think my issues were more related to the KO2s and how squared off they were originally. I have almost 9k on it now and although it isn’t a sports car it handles great. When I first got it it grabbed every little imperfection in the road, not anymore.

View attachment 7852148View attachment 7852151

1. Carraro HS6.07 Axle front wheel bearing assembly. Vari Brake upgrade. 2. Ineos Grenadier Carraro front axle

View attachment 7852123View attachment 7852147

4. Rear FF hub Carraro Iveco 4x4. Photos from 4x4 Iveco Daily FB pages.

I refer back to SCAM built 4x4 Iveco Daily as the closest axle comparison, it has the larger model Carraro front and rear full floating axles then the Grenadier but essentially share the identical design (12 bolt cover not 9 bolt using Chevy terms). Both front and rear wheel bearings need a puller to remove the wheel hubs and a special factory tool or a custom made fixture to remove and replace the front wheel bearing with out damaging the housing. Some mechanics have reported using between 10 to 20t and some more to remove the front wheel bearing from the knuckle with their custom made jigs used in a workshop press. From what I have been told by a few who have done the job and some research the wheel bearing is pressed in from the back of the steering knuckle on to a shoulder while hub presses in from the front and is held into the bearing with the drive axle. I expect the same for the Grenadier.

When the Daily 4x4 has experienced major wheel bearing failure most have been towed to a workshop for repair while others have been successful in replacing wheel bearings as preventative maintenance with a well equipped home workshop. This has been documented in various peoples travel pages and vlogs. The rear full floating hub will require to be assembled with the bearing if it is to be carried as a spare. As a field repair with limited tooling, the wheel bearings on Grenadier and Quartermaster are going to be a job where out of the box MacGyver type thinking will be required and will be a relatively difficult task for the inexperienced DIYer to complete.

Thanks for the off-topic info. Does that mean that the front inner axle shaft assembly can't be removed without pulling the knuckle? If so, a leaky inner axle seal replacement also just got a lot more fun. I swallowed hard at the test drive when I was told the bearings were pressed in to the knuckles. Now you've given me a case of gerd. Hopefully solutions for the shadetree mechanic will be found short of complete Dana axle replacements.

I drive a Grenadier Station wagon, plus a BMW X6. I now prefer highway driving in the Ineos. It’s a pleasant experience at the destination getting out feeling refreshed and relaxed. Can’t say I have any issues getting used to driving one of the other. Have had my grenadier for just under a year now and love it.Just from reading through a history of discussions on this board I have to think these trucks are being delivered with some kind of variation in settings or tolerances from the factory.

I say that because some people drive it and say its fine on the highway at 80mph or whatever, and others report its all over the place.

Can both be true?

I guess...maybe.

Wranglers have a very similar setup and some of them report wobbles, issues, but many do not.

I think most of what we are seeing is the normal operation of a recic ball steering, but not all of it.

I had an H1 that I drove on stock tires then switched to 40s and I never felt the steering was an issue. Of course I dont think I ever drove it faster than 70mph for extended periods....Bursts of 75. Not because of the steering so much but the truck as a whole, rpms etc.

I thought it steered fine but it felt like a truck.

Because it was a truck.

Ive driven Wranglers and didnt have any issues. I see them doing 75-80 all the time on the highway.

I think we are just not used to how trucks drive.

Its just a by-product of the parts with some variances from the factory thrown in.

I do not believe all of them are perfect, I DO believe some folks are having some issues. I also believe that once the performance shops start seeing more of these we will learn more, especially in variances from truck to truck.

I had a very limited drive in a Grenadier for about 5 mins and the one I drove seemed perfectly normal to me.

Another problem is that for years manufacturers like BMW, Merc, and Porsche have been designing sedans and SUVs that handle closer to sports cars to one degree or another and folks have grown accustomed to that.

To me, those vehicles are the anomaly.

nope. Ain't gonna happen. The whole field repair thing went out the window long ago.Thanks for the off-topic info. Does that mean that the front inner axle shaft assembly can't be removed without pulling the knuckle? If so, a leaky inner axle seal replacement also just got a lot more fun. I swallowed hard at the test drive when I was told the bearings were pressed in to the knuckles. Now you've given me a case of gerd. Hopefully solutions for the shadetree mechanic will be found short of complete Dana axle replacements.

I suggest anyone still entertaining that notion to seek profesional help.

The entire vehicle is a modern, tied to a captive dealer repair network, heavy duty suv.

It would be interesting if someone asks their Service Center what the official Ineos estimate of labor and parts to replace the pressed bearings would be as calculated in their service computer. 200000km (125000mi) isn’t a super long run.View attachment 7852148View attachment 7852151

1. Carraro HS6.07 Axle front wheel bearing assembly. Vari Brake upgrade. 2. Ineos Grenadier Carraro front axle

View attachment 7852123View attachment 7852147

4. Rear FF hub Carraro Iveco 4x4. Photos from 4x4 Iveco Daily FB pages.

I refer back to SCAM built 4x4 Iveco Daily as the closest axle comparison, it has the larger model Carraro front and rear full floating axles then the Grenadier but essentially share the identical design (12 bolt cover not 9 bolt using Chevy terms). Both front and rear wheel bearings need a puller to remove the wheel hubs and a special factory tool or a custom made fixture to remove and replace the front wheel bearing with out damaging the housing. Some mechanics have reported using between 10 to 20t and some more to remove the front wheel bearing from the knuckle with their custom made jigs used in a workshop press. From what I have been told by a few who have done the job and some research the wheel bearing is pressed in from the back of the steering knuckle on to a shoulder while hub presses in from the front and is held into the bearing with the drive axle. I expect the same for the Grenadier.

When the Daily 4x4 has experienced major wheel bearing failure most have been towed to a workshop for repair while others have been successful in replacing wheel bearings as preventative maintenance with a well equipped home workshop. This has been documented in various peoples travel pages and vlogs. The rear full floating hub will require to be assembled with the bearing if it is to be carried as a spare. As a field repair with limited tooling, the wheel bearings on Grenadier and Quartermaster are going to be a job where out of the box MacGyver type thinking will be required and will be a relatively difficult task for the inexperienced DIYer to complete.

Had the same experience after picking up my Grenadier,definitely had to put in steering effort to keep it from wandering to centre of the road.Did intend taking it to Tru Trac for a wheel alignment,but after covering >3K kms,it seems to have improved.It has had a couple of software updates at the agent so they may have corrected the castor,do not know, as nothing has been written in the logbook. Put a few more miles on the clock and see if it improves.I just got through all 11 pages of this thread. Thanks to everyone that contributed so far. I'm here to report I have the same issue. I picked up my Grenadier from SoCal and drove it 6+ hours to NorCal and the handling was all over the place. It was definitely a sketchy drive especially at speeds around 75mph+ and on curves. It was like I had to super focus on driving and keep both hands on the wheel at all times.

For folks that have this issue "corrected": was it a caster adjustment that ultimately fixed it for you?

Similar threads

- Replies

- 7

- Views

- 374

- Replies

- 6

- Views

- 499

- Replies

- 6

- Views

- 623