maybe a dumb question but if your going to use the lift why not replace the CV shafts with the double cardan with a custom made driveline hell of a lot cheaper than oem spare.

The Grenadier Forum

Register a free account today to become a member! Once signed in, you'll be able to contribute to the community by adding your own topics, posts, and connect with other members through your own private inbox! INEOS Agents, Dealers or Commercial vendors please contact admin@theineosforum.com for a commercial account.

Double Double Cardan shafts have been notoriously a pain in the butt. A shaft with a double Cardan at one end with virtually no Joint angle and a Double Cardan at the other end works quite well. This was actually a factory fix for Land Rover on the Series II Discovery. They originally tried Ujoint phasing which had mixed results.maybe a dumb question but if your going to use the lift why not replace the CV shafts with the double cardan with a custom made driveline hell of a lot cheaper than oem spare.

However if you have a notable angle at both the transfer case and the differential this type of layout won't work. Enter the "Double" double Cardan shaft. This type of shaft was kinda never really supposed to be. This is due to the method used to locate the two Ujoints in the double Cardan. There is a ball and a pin along with a socket in each double Cardan joint. This design is rather loose in relative terms. This looseness is generally well tolerated at lower angles and goes unnoticed by the operator for many thousands of miles. But eventually you will find a rebuild or even just some fresh grease can dramatically smooth out the drive shaft.

Now, put two of those joint in a drive shaft and things can get strange. Depending on the severity of the angles you have the joints tend to wear more or less of course. As one wears it can cause the other to wear faster. This cycle can go very fast and quickly lead to vibrations that are notable by the operator. The shaft won't necessarily fail, but they can get pretty rough in relative terms. Especially when compared to typical CV joints.

Double Cardans work well when used at more traditional Ujoint angles with occasional use outside the norm. But if they live outside the norm all day long then they do start to wear quickly. And with their huge mass they can be felt very easily even with minimal wear.

Double Double Cardans with all the additional joints and components as they wear (especially around the centering balls) will start to rotate about its axis sort of like two people swinging a loose jump rope between them. You’ll never get them to run completely true or without vibration over the long haul so they would be more of a bandaid not something I’d want to trust to daily driving or highway speeds as a permanent solution.

Of course there are folks who will swear by them and have never had any issues but all those extra joints introduce additional failure and maintenance points so keep that in mind.

Of course there are folks who will swear by them and have never had any issues but all those extra joints introduce additional failure and maintenance points so keep that in mind.

Last edited:

I know of one double cardan available for the Grenadier and one other in development. The one that is available was 2x the cost of a replacement OEM front driveshaft.maybe a dumb question but if your going to use the lift why not replace the CV shafts with the double cardan with a custom made driveline hell of a lot cheaper than oem spare.

That makes perfect sense thank you very much for that lengthy description! I assume probably run the risk of transfer case output shaft damage with more rotational wieight also?Double Double Cardan shafts have been notoriously a pain in the butt. A shaft with a double Cardan at one end with virtually no Joint angle and a Double Cardan at the other end works quite well. This was actually a factory fix for Land Rover on the Series II Discovery. They originally tried Ujoint phasing which had mixed results.

However if you have a notable angle at both the transfer case and the differential this type of layout won't work. Enter the "Double" double Cardan shaft. This type of shaft was kinda never really supposed to be. This is due to the method used to locate the two Ujoints in the double Cardan. There is a ball and a pin along with a socket in each double Cardan joint. This design is rather loose in relative terms. This looseness is generally well tolerated at lower angles and goes unnoticed by the operator for many thousands of miles. But eventually you will find a rebuild or even just some fresh grease can dramatically smooth out the drive shaft.

Now, put two of those joint in a drive shaft and things can get strange. Depending on the severity of the angles you have the joints tend to wear more or less of course. As one wears it can cause the other to wear faster. This cycle can go very fast and quickly lead to vibrations that are notable by the operator. The shaft won't necessarily fail, but they can get pretty rough in relative terms. Especially when compared to typical CV joints.

Double Cardans work well when used at more traditional Ujoint angles with occasional use outside the norm. But if they live outside the norm all day long then they do start to wear quickly. And with their huge mass they can be felt very easily even with minimal wear.

This is accurate. As well as the pinion flange on the diff. Also, when they come apart due to negligence they can cause a hell of a lot of damage. I've seen regular front drive shafts come through the floor of a Defender 90. Imagine how much worse it would be with the extra mass.That makes perfect sense thank you very much for that lengthy description! I assume probably run the risk of transfer case output shaft damage with more rotational wieight also?

Edit: to clarify a good condition Double Cardan at the T-case side is fine. But excess wear of the joint could add a lot of extra stress on the T-case output.

I know of one double cardan available for the Grenadier and one other in development. The one that is available was 2x the cost of a replacement OEM front driveshaft.

With current knowledge you can have a double double Cardan shaft for sub $1k all day long. In fact I bet you could get under $500 if you had to. But I am not convinced this is the best option.

Last edited:

I hate repairing the double cardon centering ball.

There are less than convenient for sure.I hate repairing the double cardon centering ball.

and where might I get one for the Grenadier at that price? I'm all for giving it a shot, especially at under $500.00.This is accurate. As well as the pinion flange on the diff. Also, when they come apart due to negligence they can cause a hell of a lot of damage. I've seen regular front drive shafts come through the floor of a Defender 90. Imagine how much worse it would be with the extra mass.

Edit: to clarify a good condition Double Cardan at the T-case side is fine. But excess wear of the joint could add a lot of extra stress on the T-case output.

With current knowledge you can have a double double Cardan shaft for sub $1k all day long. In fact I bet you could get under $500 if you had to. But I am not convinced this is the best option.

and where might I get one for the Grenadier at that price? I'm all for giving it a shot, especially at under $500.00.

It's a relatively standard flange conversion. You can have a local driveline shop build one. There are 1350 and 1310 Double Cardan joints conversions readily available. 1310 is plenty big and allows higher angle in stock form.

I will hopefully have a source worked out this coming week for a decent shaft.

Last edited:

Seems like a good shaft should be around 1200.00 or less. I added the teraflex to be safe, and while no failures, I have un-except able vibrations.

My understanding is that the Teraflex isn't any stronger than the factory CV nor does it support a higher angle.Seems like a good shaft should be around 1200.00 or less. I added the teraflex to be safe, and while no failures, I have un-except able vibrations.

Try tom woodsIt's a relatively standard flange conversion. You can have a local driveline shop build one. There are 1350 and 1310 Double Cardan joints conversions readily available. 1310 is plenty big and allows higher angle in stock form.

I will hopefully have a source worked out this coming week for a decent shaft.

Try tom woods

I have several Tom Woods shafts so yes they are on my list of resources.

Please keep me it the loop with what you get figured out. I live in Keller, TX - 6k miles, 2.5" lift, vehicle is starting to hum at higher speeds, seems like I have a potential ticking time clock.It's a relatively standard flange conversion. You can have a local driveline shop build one. There are 1350 and 1310 Double Cardan joints conversions readily available. 1310 is plenty big and allows higher angle in stock form.

I will hopefully have a source worked out this coming week for a decent shaft.

Thanks

Dan

Better do a visual check of your CV. Mine started acting up on a few drives back and forth between Plano and Boyd, TX just west of you. You do not want the shaft to come apart. It will take a lot of expensive stuff out if it does. Swapping in a new CV or even a whole drive shaft is very easy and cheap insurance.Please keep me it the loop with what you get figured out. I live in Keller, TX - 6k miles, 2.5" lift, vehicle is starting to hum at higher speeds, seems like I have a potential ticking time clock.

Thanks

Dan

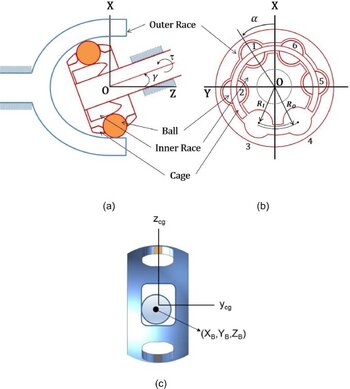

On 2.5” lifts how sharp is the CV joint angle at both the differential and transfer case ends in real terms? The driveline is not centered down the length of the vehicle so there would be contributing lateral angles for each CV joint as well. I would assume as the bearings inside the cup run closer to the extreme ends of the outer race they are less supported and more micro-flexing in the cup occurs resulting heat buildup?

Likewise, the outer rubber cover would go from fully compressed, to fully stretched, back to compressed each full rotation encountering its own fatigue/heat cycling which causes the boot to fail. I believe CV joints in general can operate up to approx. 45 degrees of angle but is that for sustained high speed operation or intermittent periods? It’s obvious angles play a lot into joint longevity and I’m not offering any solutions here but just curious about the actual science behind the operating scenarios and failure rates for lifted rigs.

Likewise, the outer rubber cover would go from fully compressed, to fully stretched, back to compressed each full rotation encountering its own fatigue/heat cycling which causes the boot to fail. I believe CV joints in general can operate up to approx. 45 degrees of angle but is that for sustained high speed operation or intermittent periods? It’s obvious angles play a lot into joint longevity and I’m not offering any solutions here but just curious about the actual science behind the operating scenarios and failure rates for lifted rigs.

Attachments

The boot is the problem. I threw an angle gauge on it the other day but need to take a moment to redo it for more accurate numbers. The T-case side is a touch harder to find a good flat reference point without removing the shaft.On 2.5” lifts how sharp is the CV joint angle at both the differential and transfer case ends in real terms? The driveline is not centered down the length of the vehicle so there would be contributing lateral angles for each CV joint as well. I would assume as the bearings inside the cup run closer to the extreme ends of the outer race they are less supported and more micro-flexing in the cup occurs resulting heat buildup?

Likewise, the outer rubber cover would go from fully compressed, to fully stretched, back to compressed each full rotation encountering its own fatigue/heat cycling which causes the boot to fail. I believe CV joints in general can operate up to approx. 45 degrees of angle but is that for sustained high speed operation or intermittent periods? It’s obvious angles play a lot into joint longevity and I’m not offering any solutions here but just curious about the actual science behind the operating scenarios and failure rates for lifted rigs.

Is it just a replacement for a standard jeep one then? it would be interesting to know for sure whether it can handle a higher angle.My understanding is that the Teraflex isn't any stronger than the factory CV nor does it support a higher angle.

Agreed, a failed boot is a major cause as it allows debris in and quickly destroys the joint. Curious if an additional standard bellow style boot (one with the right dimensions) could be fitted as an additional layer over the existing one?The boot is the problem. I threw an angle gauge on it the other day but need to take a moment to redo it for more accurate numbers. The T-case side is a touch harder to find a good flat reference point without removing the shaft.

Attachments

Last edited:

Similar threads

- Replies

- 168

- Views

- 8K

- Replies

- 4

- Views

- 309

- Replies

- 23

- Views

- 2K