- Local time

- 2:29 PM

- Joined

- Aug 24, 2022

- Messages

- 2,470

My son’sYour own 3d printer or third party

Register a free account today to become a member! Once signed in, you'll be able to contribute to the community by adding your own topics, posts, and connect with other members through your own private inbox! INEOS Agents, Dealers or Commercial vendors please use the contact us link at the bottom of the page.

My son’sYour own 3d printer or third party

@IG_in_AZ,I have to agree, I can get an Ender 3 V3 SE with rolls of black and orange PLA filament for not much more than the cost of one tray and I can make them for other USA guys (maybe sell for like $50 and it would pay for the setup after 5). I wasn't planning on getting into 3d printing, but it's not cost effective to contract it out. Thank you so much for your design work and advice! I know absolutely nothing about engineering, CAD or anything of the sort.

I priced a local third party print and it came back at $360, so I bought the printer instead.Your own 3d printer or third party

I've had mine printed for 130,5 Eur in Germany, Should arrive by tomorrowI priced a local third party print and it came back at $360, so I bought the printer instead.

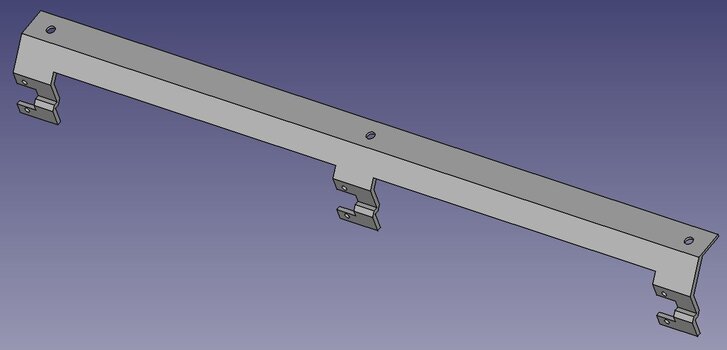

It's for an ancient form of currency called coins. He stated in previous post that he carries coins in it for those occasions where he needs a coin to complete a transaction.@chrsbe just printed mine. Thanks for the design of the tray!

But one question: why you designed the round pocket like this? I mean that one where you putted the chewing gum in. Don’t understand which purpose the lower „3-circle-pocket“ got. To put the chewing gum there they are not necessary. Hope you understand what I meansee also my attached photo.

It's for an ancient form of currency called coins. He stated in previous post that he carries coins in it for those occasions where he needs a coin to complete a transaction.

Depends on the firmware and the printer. Some can resume, others can't.What happens if there is a power cut. Does the printer just carry on where it left off?

I rotated it 90 degrees so it printed upright (all supports underneath, none inside). Sliced it in Cura using tree supports which used much less material and cut the time. Took 18 hours on my AnkerMake 5C at approx half speed in 0.2mm PLA+.How long did your prints take?

At 0.1mm resolution with all the supports and the rest being standard settings, my slicer says 3d 1h on an Ender 3 and still 1d 21h on my Voron.

At 0.2 mm the Ender takes 1d 21h and the Voron 1d 3h.

My sons Bambu did it in about 3 hoursMy printer (cr10 V3) did it in 1d 7h at 0,2mm resolution. I think it is time for a fast bambulab for Christmas

Same, I ordered a printer yesterday. It should be here next week. So, fellow Grenadiers, the US is about to have a distribution center for cubby trays. I've ordered black and orange filament. I'll have to pay @chrsbe a royalty, I think.I priced a local third party print and it came back at $360, so I bought the printer instead.

He has corrected me and told me it took 5 hours 40mins although it is possible to use a faster setting which probably could have completed in closer to 3 hoursMy sons Bambu did it in about 3 hours

We share, we say "thank you" if we want (would be nice), no royalty, no copyright, I hope this is the purpose of this forum, otherwise I leaveI'll have to pay @chrsbe a royalty, I think.