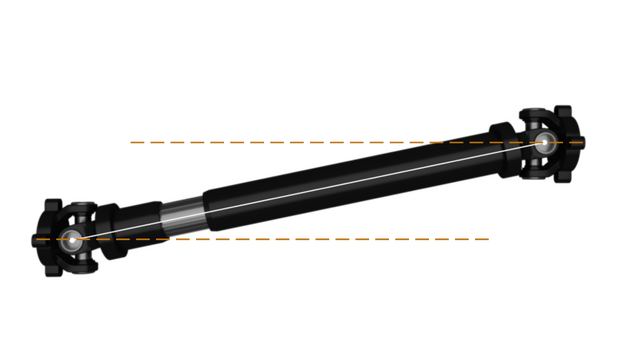

Yea, but that picture only applies to shafts without dc’s or cv’s, and being that we have cv’s, it doesn’t explain anything.Those are U Joints and not CV's but many attempts have been made to develop a double cardon style driveshaft then they have been met with harmonic issues.

For anyone confused,

Just to be clear, a Ujoint, accelerates and decelerates thru its motion, and to offset that force, and prevent vibration, the joint at the other end needs to be of the same mass, angle, and 90* out of phase to offset.

A CV has a Constant Velocity, and doesn’t suffer from this.

A DC or Double cardon, has built in offsetting acceleration, so it is NoT actually a CV. It’s advantage being, it’s easier to make and easier to make durable in small diameter package. You can make a true ball and cage CV just as strong, but you may not like the size of it.

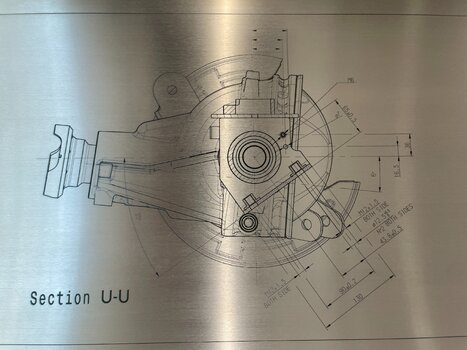

The tried and true solution for extreme angles has been to put ONE DC at the t case, and point the pinion u joint directly at the output of the DC to eliminate any angle at the pinion, and any acceleration forces… nominally. DC’s lack the machining precision of CV’s and this cut and turn system typically works for 4X4 speeds on the highway. It’s nothing you would want at 220mph. In big lifted trucks some of that vibration bubba is feeling at 90mph may not be the tire lugs alone.

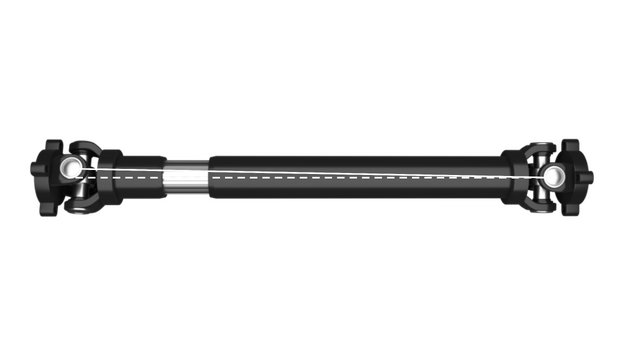

The aftermarket shafts attempted were trying to eliminate the boot failure of the CVs without resetting any angles, so they eliminated the CV’s in favor of a double cardon at each end…. The effect on each other would be like squaring any small vibrations from machining imperfection each unit would have, and while admirable for the attempt, was a really tall ask. Even IF they worked out of the box, I wouldn’t think you’d be very happy with the durability. It wouldn’t take much wear at all for a tiny vibration to start and it would head downhill pretty quickly from there.

The moral of the story is… someone needs to get ahold of a wrecked unit for a front axle, and play with cutting and turning it. Ain’t gonna be me! I’ll be happy to follow once someone works it all out, though.