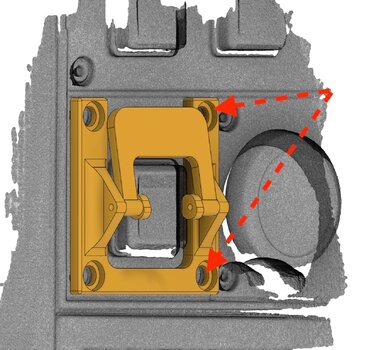

Interesting. I could imagine a mount for a phone or something where it sat in and allowed permanent deactivation and was attached with the four screws. Very low though to be glancing down.3d print something that you can screw into that square.

The Grenadier Forum

Register a free account today to become a member! Once signed in, you'll be able to contribute to the community by adding your own topics, posts, and connect with other members through your own private inbox! INEOS Agents, Dealers or Commercial vendors please contact admin@theineosforum.com for a commercial account.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

I present the Auto Start/Stop Temporary fix

- Thread starter IslandFalconer

- Start date

-

- Tags

- auto

Already did the Zip tie, it popped out, also hard to grab.

I don't know why you don't think this is a 3d print type job. I printed a tractor bucket that was 1/2 mm thick and it was crazy strong.

Appreciate the encouragement!

Meh, there are tools and materials for everything. I use 3D printing largely for prototyping parts that will eventually be machined out of steel or the like. Also makes for great jigs.

I guess my point is an appropriately sized zip tie or some light metal that can be cut with heavy duty kitchen shears is faster than drawing up a part, prepping the printer and waiting for it to print. And the thin nature of the wedge needed could end up leaving a chunk of plastic in your switch if the layers don't adhere well.

Now, draw up something that covers the switch completely and is held on by the four screws and doubles as some other fun item!! I'm in on that idea.

On a side note, I got to mess with one of the first viable small laser metal sintered 3D printers ever built. Probably back around 2004-2005. Was an amazing thing back then. Got to watch them make an anatomically correct titanium femur. Same weight as the real femur.

I'm with Eric. It's like when a pilot gets into a plane there are a bunch of switches he flips while getting ready to move. I go through the process below everytime I start the motor.I present my auto stop/start fix

1. Start Motor

2. Allow Bluetooth and carplay to come on

3. Hit the auto start/stop button

4. Hit the favorites button to disable the speed clicking sound

5. Shift into a gear and roll out

@Ingemar agrees!I'm with Eric. It's like when a pilot gets into a plane there are a bunch of switches he flips while getting ready to move. I go through the process below everytime I start the motor.

1. Start Motor

2. Allow Bluetooth and carplay to come on

3. Hit the auto start/stop button

4. Hit the favorites button to disable the speed clicking sound

5. Shift into a gear and roll out

Nah.. that novelty got old real fast lol… pretend to be a pilot…I'm with Eric. It's like when a pilot gets into a plane there are a bunch of switches he flips while getting ready to move. I go through the process below everytime I start the motor.

1. Start Motor

2. Allow Bluetooth and carplay to come on

3. Hit the auto start/stop button

4. Hit the favorites button to disable the speed clicking sound

5. Shift into a gear and roll out

Awesome video! Thanks for sharing.

I am a pilot, and I don’t want to that when getting in my truck. Secondly getting my DHC-2 started and in the air takes fewer button clicks. Turn on mags, prime, start. That’s it. So this idea of a “preflight” on a brand new Truck is nonsense.I'm with Eric. It's like when a pilot gets into a plane there are a bunch of switches he flips while getting ready to move. I go through the process below everytime I start the motor.

1. Start Motor

2. Allow Bluetooth and carplay to come on

3. Hit the auto start/stop button

4. Hit the favorites button to disable the speed clicking sound

5. Shift into a gear and roll out

Awesome video! Thanks for sharing.

@Ingemar is a long term member of the forum. He was one of the three Hard Way Home contest winners who collected his vehicle in Morocco in early 2023. He has a great Youtube channel about his Grenadier. Ingemar was figuring it out before most others.

Ingemar's cockpit video is just a bit of fun. He's not a wannabe pilot. Ingemar was a career airline pilot for 20+ years before moving across to business aviation.

Being a pilot I can say the worst part of a flight is the preflight. As well, the trend these days is to make new aircraft more like modern cars. Turn the key and go.

Additionally, on my truck, if I push the FAV button too soon it will crash CarPlay and never get to the FAV screen anyways. So I have to wait for a bit, I usually wait until I break the speed limit and the truck chirps at me. Then I disable while driving which is nice and distracting.

Additionally, on my truck, if I push the FAV button too soon it will crash CarPlay and never get to the FAV screen anyways. So I have to wait for a bit, I usually wait until I break the speed limit and the truck chirps at me. Then I disable while driving which is nice and distracting.

Agreed It’s the dumbest thing ever…I am a pilot, and I don’t want to that when getting in my truck. Secondly getting my DHC-2 started and in the air takes fewer button clicks. Turn on mags, prime, start. That’s it. So this idea of a “preflight” on a brand new Truck is nonsense.

Here's the file my son put together for me. Hope it works as well for you guys as it did for me.

Here's the file. Had to put it into a zip file to upload it to the forum as the system doesn't allow stl files. Let me know if you have any trouble using it.@TelRidan - Do you mind sharing your print file?

Attachments

I hear CheckMate is releasing a special edition laminated Grenadier list.Nah.. that novelty got old real fast lol… pretend to be a pilot…

I am working on a button to flick switch converter....

Wouldn't it be easier to unscrew the 4 screws and jumper the contact under the button?

Attachments

good luck

Please put my name on one of the first batch.

It's not that you can't do that, but it's more complicated than you would think. It's part of an integrated board. There are no individual dash components contrary to how it looks.Wouldn't it be easier to unscrew the 4 screws and jumper the contact under the button?

The 3D print is cool and all but not as sneaky and unobtrusive than the small black clip. To each their own though.

Why a switch? When would you ever want to turn it off?Please put my name on one of the first batch.

There’s some worksites I work on where I don’t mind it. Depends on the situation. You’re right often it’s a nuisance.Why a switch? When would you ever want to turn it off?

That's awesome. I like having auto start/stop as an option but want it to be default off.

Messing with the wiring in the switch panel may be more difficult than people assume, as the entire panel is a single sealed unit and probably has an integrated ECU. I'd prefer not to do that under warranty... or at least not be the first person to try!

Similar threads

- Replies

- 0

- Views

- 277

- Replies

- 16

- Views

- 2K

- Replies

- 260

- Views

- 13K

- Replies

- 7

- Views

- 1K