Just a question- how often have you used that equipment? I have used it rather frequently and can not join your oberservationsbeware... front plate Letech winchbumper is very thin and made of ... aluminium ! So, it is weak and the welds are cracking if you winch in an angle.

Mister Letech told me in Germany : you only can winch straight, not in an angle

So, Letech winchbumpers are very expensive and just for show. They are worthless if you use them for what they were made for

didi

Ghent

View attachment 7861546

The Grenadier Forum

Register a free account today to become a member! Once signed in, you'll be able to contribute to the community by adding your own topics, posts, and connect with other members through your own private inbox! INEOS Agents, Dealers or Commercial vendors please contact admin@theineosforum.com for a commercial account.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Winch installed

- Thread starter NoAge Hunter

- Start date

-

- Tags

- bumper letech letech winch winch

Thats poor! Winching at an angle is not ideal and best avoided, but you still want to be able to do it when the need requires..

Not all jurisdictions are the same; the UK is quite permissive, owners can fit almost anything provided it does not stick out and have sharp edges.

The Germans have it particularly hard, no TUV approval, you cannot legally fit it. Part of annual inspections is proving you have the approvals for any aftermarket alterations. It makes for beautiful kit but some scary prices.

(warning, i realized after i wrote my wall of text that i went down a rabbit hole... But this stuff interests me and in a former life i worked on some of this stuff)...

I really like that the US is generally leading with performance based regulations instead of technology and design regulations.

Once you own the car each state gets to determine which changes are tolerable and which are not. In my state, California, emissions changes are of a particular public interested which makes them tracked and only CARB (CA air resources board) approved equipment can be installed into vehicles.

At the federal level (which really isn't that involved in what happens after the vehicle is sold) they basically determine if the cost of the requiremen eclipse the public good. To make a tangible example, all new cars must have reverse cameras because the goverment has calculated that the benefit to the public in reducing back up accidents is larger than the cost of requiring the public to purchase the cameras. The performance standard are straight forward: "The field of view must include a 10-foot by 20-foot zone directly behind the vehicle. The system must also meet other requirements including image size, linger time, response time, durability, and deactivation."

There is a bunch of recalls and consent orders in the industry right now because a couple of manufacturers cameras aren't starting up fast enough after the car enters reverse.

i know they studied the excess speed warning system like our grenadiers have but came to the conclusion that the economic benefit to the public was less than the cost imposed to the public by requiring these systems. That may change over time but this is what the analysis took them.

After the vehicle is sold you can modify it. Its up to your state to determine if that modification is allowed or not. most states doesn't care too much on wheter you put on bigger wheels or change bumpers. if you injure someone because of the modification, its a matter of liability which can be handled by the parties directly. This only changes when it becomes large enough of a concern for the population that the state has to regulate it. In CA there is an excess speed warning bill lingering in comittee to force the speed warning that ineos has onto all new cars.

Having said all of that, i expect there to be no major changes to vehicle regulations at the federal level in the next 4 years regardless who gets elected president. Biden will push the transportation secretary on aviation safety via FAA and Trump will revert back vehicle emissions standards to what he put in place when he was president. And that is all that will happen. I'm pretty happy about that because i like modifying my vehicles..

Very Nice!Today I got my winch and bumper installed (LeTech Kit). I am so much looking forward to test it tomorrow!

What I really like already is the quality and design of the bumper and that one has easy access to the winch.View attachment 7844296

Hello

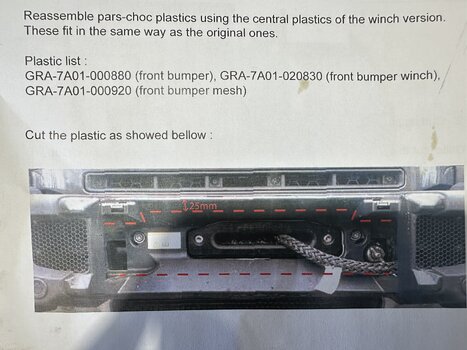

I am looking for plastics of the winch version...

met de code GRA-7A01-020830 (voorbumperlier)

Mocht iemand deze nog hebben liggen omdat er een andere lierbumper op de auto is gemonteerd, dan wil ik hem graag overnemen.

Thank you in advance for your efforts!

Greetings,

Rob Melchels

Attachments

Awe some!Today I got my winch and bumper installed (LeTech Kit). I am so much looking forward to test it tomorrow!

What I really like already is the quality and design of the bumper and that one has easy access to the winch.View attachment 7844296

Do you have the original winch bumper parts van the original Ineos? I am looking for them...

Thanks for your answer

Greetings,

Rob

Sorry Rob- my original Bumper Part was not that kind for a winch. Otherwise I would be happy to sell it to you.Awe some!

Do you have the original winch bumper parts van the original Ineos? I am looking for them...

Thanks for your answer

Greetings,

Rob

Ok thankx for your answer.Sorry Rob- my original Bumper Part was not that kind for a winch. Otherwise I would be happy to sell it to you.

Good day, greetings,

Rob

Often and I am not alone... Reulsport Belgium has the same problems with LETECH winch bumpers which are made too light in Germany.Just a question- how often have you used that equipment? I have used it rather frequently and can not join your oberservations

The company that distributes LETECH in Belgium = https://www.dgtuningadventure.com made a heavy duty version of it (in decent steel).

didi

Thanks for the link.Often and I am not alone... Reulsport Belgium has the same problems with LETECH winch bumpers which are made too light in Germany.

The company that distributes LETECH in Belgium = https://www.dgtuningadventure.com made a heavy duty version of it (in decent steel).

didi

Congrats on getting the LeTech Kit winch installed! It sounds like a top-tier setup, especially with the remote control features and power outlets. It’s always great when everything is streamlined for easy use, especially when you’re out in the field. That price tag is hefty, but it’s good to know it’s all TÜV-approved, which is crucial in Germany. Can’t wait to hear how it performs after you test it in the woods—sounds like a solid investment for serious off-roading!

Is that Winchbumper really so weak? usually i was also considering this one for mine, because i don't like the Taubenreuter being installed so low. And also the installation of the letech is by far easier. Anyone else ever got this experience? How thick is the material? was it maybe just weak welds?beware... front plate Letech winchbumper is very thin and made of ... aluminium ! So, it is weak and the welds are cracking if you winch in an angle.

Mister Letech told me in Germany : you only can winch straight, not in an angle

So, Letech winchbumpers are very expensive and just for show. They are worthless if you use them for what they were made for

didi

Ghent

View attachment 7861546

That is one astounding piece of garbage. Letech must be owned by smitttybuilt.

Words of wisdom. I'll remember that, the next time I'm planning on where to get stuck. I'm not sure why I didn't think of doing this 1000 pulls ago.Thats poor! Winching at an angle is not ideal and best avoided, but you still want to be able to do it when the need requires..

If that's the way you stow the winch line, pulling it in nice and tight makes it more difficult for the casual jagoff to mess with shackle pin. "Effort" dissuades 9 of 10 pricks.beware... front plate Letech winchbumper is very thin and made of ... aluminium ! So, it is weak and the welds are cracking if you winch in an angle.

Mister Letech told me in Germany : you only can winch straight, not in an angle

So, Letech winchbumpers are very expensive and just for show. They are worthless if you use them for what they were made for

didi

Ghent

View attachment 7861546

Red do one now have a lookMay I ask the overall cost of this conversion? Including spring upgrade?

1000 pulls? You must get stuck a lot! I actually have done thousands of pulls…but I work in forestry.. Forestry winches are usually designed to wind onto the drum smoothly so will function at an angle , but you can easily put a machine on its side if the angle is too extreme. In a 4x4 like I said you really want to be less than 20 degrees either side of centre otherwise all the rope will spool up on one side of the drum.. and you could also damage the winch or the vehicle. A short pull at an extreme angle might be ok, but its best avoided..Words of wisdom. I'll remember that, the next time I'm planning on where to get stuck. I'm not sure why I didn't think of doing this 1000 pulls ago.

I found a real winching video from us 11 years ago …

Yea. Lost count for sure. Show me a fella that says he plays rugby but hasn't been busted up time after time, and I'll show you a guy that plays barrstool rugby.1000 pulls? You must get stuck a lot! I actually have done thousands of pulls…but I work in forestry.. Forestry winches are usually designed to wind onto the drum smoothly so will function at an angle , but you can easily put a machine on its side if the angle is too extreme. In a 4x4 like I said you really want to be less than 20 degrees either side of centre otherwise all the rope will spool up on one side of the drum.. and you could also damage the winch or the vehicle. A short pull at an extreme angle might be ok, but its best avoided..

I found a real winching video from us 11 years ago …View: https://youtu.be/P59obAokKks?si=Q95r9ySnWMVtozNs

Equipment needs to be designed for you to be stuck and any angle. You're stuck. Unless what you wanted was to be stuck, and you planned out how you're gonna be stuck, the idea there's an angle you want to be stuck at is ridiculous. What you are is stuck, and like any other stuck, you need to know how to use your equipment to get unstuck. This isn't forestry. Who the hell cares about forestry? Hey, we do Auxiliary power installations. Tugging, hoisting, rigging, all with equipment with more mass and power than a truck. What does that have to do with 4x4 winching situations? Hmmm... Safety procedures, Equipment inspection and PM, Rigging... And thats about it. 99% of the situations in one, have nothing to do the other. Vehicle recovery is whole different art. Nothing is planned, nothing is ideal. House painters and Picasso both used a brush and paint, but that's about where the overlapped stopped.

My favorite stuck was after being lead down a rocky mountain pass and the path just stopped 2 miles in. No turn around, steep slope up and steep slop down, and a couple sections where reverse wasn't doable. We all Had to do a 180. The solution for me was to run the front winch line to tree behind me, inflate tires to 60psi so they would drag easier sideways without losing a bead (potential tragedy), and hammer it in reverse cranking the wheel so the ass of the rig went up the slope, no matter the scraping of the bumper or protestations of the earth. Pointing down at over 50*, the winch line was at 100* right. (not "ideal") While nearly standing in the cab, I would slip it 6" forward back onto the path, and drag the front end with the winch a little. repeat repeat repeat. I got the rig realigned 180 without plummeting off the side. Gotta love a challenge. Nothing broke.

Point being Tom, in 4x4 land your 20* rule is an inapplicable observation that has noting to do with real life situations a reader may find themselves. The only time's I've had straight pulls where when I could line myself up to extricate someone else. (I suppose that may be like pulling logs) If your equipment can't handle the scenario I just described, go drive a subaru outback, and don't dare adventure in the Andes. Stick to greenlaning and club events on known trails where someone else can save you by lining up at 20 or less, and for gods sake prevent disasterous bunching on the spool line and don't let them hook up until they do..

As to the spooling on one side of the drum, first, you don't load a drum to 100% capacity. (8274's with 100-110ft is my MO) Unlike wire rope, poly line of the diameter and sheathing used on light duty truck winches NEVER re spools like a new thimble full of thread. It's not a godsend of perfection, it does have some downsides like that, abrasion, and icing. After EVERY trip the line gets pulled, washed to rid it of abrasives, inspected and respooled. It ain't steel. It doesn't act like steel, so don't treat it like steel. It needs PM. Going way back to original questions on this forum about the 15m of line on an oem winch, that's one of the reasons I said it was a god awful design by someone that doesn't winch. It's an RC winch. You only have 40ft of usable line on full spool for perfect conditions, which, if conditions were perfect or predicable, you wouldn't be stuck, now would ya? Which in turn leads to winch access... Hidden winches suck. Period. you always want access to the spool and easy examination of any rigging equipment that you need to save your skin.

Thats ma story, and I'm stickin' to it.

Congrats on getting the LeTech Kit winch installed! It sounds like a top-tier setup, especially with the remote control features and power outlets. It’s always great when everything is streamlined for easy use, especially when you’re out in the field. That price tag is hefty, but it’s good to know it’s all TÜV-approved, which is crucial in Germany. Can’t wait to hear how it performs after you test it in the woods—sounds like a solid investment for serious off-roading!

it is poor quality junk !

What about the AFN bumper? its also that bad? anyone with any experience about that?

Finally i found a dealer for AFN in germany. The bumber looks quiet nice and seems to be rigid. Bad news are, that it is not yet available. As G-Classics told me, it will be in production from January on. So i guess i'll wait for it. If anyone is curious about this bumper, you could check out pictures of the prototype on www.g-classics.com/shop/48002923

The final version will also have probably holes for the parking sensors. I will let you all know when i was able to take a first look at the final version. I am really curious about this bumper

The final version will also have probably holes for the parking sensors. I will let you all know when i was able to take a first look at the final version. I am really curious about this bumper

Similar threads

- Question

- Replies

- 0

- Views

- 354

- Replies

- 14

- Views

- 1K

- Replies

- 27

- Views

- 1K

- Replies

- 21

- Views

- 914