I've been trying to work through the math of proper offset for aftermarket wheels considering the below. Note I have the +2.5 inch Eibach springs.

OEM: 7.5" Wheel, 265mm / 14.33" wide KO2 Tire, +55 offset (the 17" steelies)

Desired Tire: KO3 LT315/70R17, 12.4" wide

Trying to solve for optimal offset for an 8.5" and a 9.0" wheel. I'm ok with some extra poke, main priorities obviously being clearance and minimizing any additional stress.

Optimal offset will be determined by what poke you want, not the opposite.

Both the offset and the rim width will affect this.

stock is 7.5x55. making it 7.5x30 moves the tire out 25mm or 1" nominal poke vs stock. now an 8x30 is not the same, as the center line has shifted .25" or 12.7mm. so that gets added to both sides and the pole is now about 1.25"

What you need to do is determine if poke or internal tire interference is most important and work your way inward from there.

Keep in mind why tires interfere.

solid axles tuck, meaning as the axle rotates on its pivot point, the tire will tilt inward at the top. which is good and an advantage over IFS, depending on the arm length.

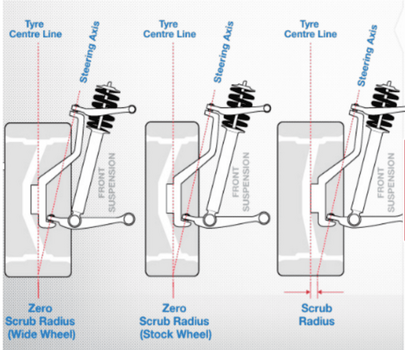

Another factor is the scrub radius. I have no idea what the kingpin center line is to the hub mounting surface. As such it'll be tough to determine how close the outer edges of the tire will be to interference points when in full lock.

Sitting around here somewhere I did a sketch to rehoop the stock steelies where I drew out multiple BS with multiple hoop widths, and I'm down to 7.5-8" hoops, set to 25-30mm BS. On a Toyota I'm running 9" Interco Birddogs for 35-37" tires, but they have a real aggressive lip design that permits single digit air downs, and stock or aftermarket steel hoops won't be that way, so I'm sticking to minimum widths (to -.5") for the tire size I'm wanting. Why do you think you need an 8.5-9.0 hoop width?