The Grenadier Forum

Register a free account today to become a member! Once signed in, you'll be able to contribute to the community by adding your own topics, posts, and connect with other members through your own private inbox! INEOS Agents, Dealers or Commercial vendors please contact admin@theineosforum.com for a commercial account.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

NA Bull Bar

- Thread starter WyomingRoaming

- Start date

Thank you, it was a salesperson at Sierra and they were very sure of what they were saying. I'm still hoping they bring the OEM bar into the US in 2025.Yes it does.

The EU bumper (plastic) and US bumpers (steel) are different; US and Aus are not

Can you share the pics of the Bull barSummer Auto is selling their Bull Bar for $1000 (USD). Shipping to the US is expected to be approx $1,100 (USD).

I don't know if the US and Aussie bumpers are the same, but I do know the Aussie bull bar bolts right on to the US bumper.Thank you, it was a salesperson at Sierra and they were very sure of what they were saying. I'm still hoping they bring the OEM bar into the US in 2025.

I had mine shipped from Aus. Installed it myself in about 20 minutes.

I also know there is already a 25% tariff on Chinese steel products. CBP hit me with it because the box said "made in China" on it, despite it being shipped from Aus.

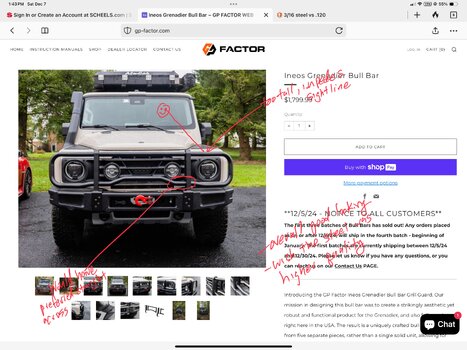

I just ordered the GP factor bull bar.

I ordered a bull bar from down under. Fit my US Grenadier perfectly.Does anybody know if the OEM bar bolts right onto our US bumpers? I just had a dealer tell me the Aus and US bumpers are different by a few inches.

We have soooooo many really good choices for bull bars and side steps. It’s hard to pick a favorite!!

To me this is a great sign that so many vendors are putting forth new products for the Grenadier. That means they also believe these vehicles will be around for some time!!

To me this is a great sign that so many vendors are putting forth new products for the Grenadier. That means they also believe these vehicles will be around for some time!!

News on the bull bar. I was at the LA Auto show last week and spoke to the Ineos Rep. he told me the rumors of it being sold here are false. He said since they can’t get it crash tested it will not be sold through the dealers at all. He said we are welcome to use after market ones or order from Australia though.

I appreciate you getting an answer, I've had non-committal responses when discussing with dealers.News on the bull bar. I was at the LA Auto show last week and spoke to the Ineos Rep. he told me the rumors of it being sold here are false. He said since they can’t get it crash tested it will not be sold through the dealers at all. He said we are welcome to use after market ones or order from Australia though.

After getting quoting in excess of 3k USD for an Australian bar, I went ahead and ordered the GP Factor variant this morning.

Owl uses DOM steel

GP Factor uses HRPO steel

ChatGPT says: DOM (Drawn Over Mandrel) steel is generally stronger than HRPO (Hot Rolled Pickled and Oiled) A36 carbon steel, though the comparison depends on the specific application and properties being evaluated. Here’s why:

Key Differences Between DOM Steel and HRPO A36:

1. Material Strength:

• DOM Steel:

• Typically made from 1018 or 1026 carbon steel, which have higher tensile and yield strengths compared to A36

• The cold-drawing process increases strength, hardness, and uniformity

• Tensile strength: ~70,000–80,000 psi (depending on the grade).

• Yield strength: ~60,000–70,000 psi.

• HRPO A36 Steel:

• A36 is a structural steel with lower strength and is designed for applications where toughness and weldability are prioritized.

• Tensile strength: ~58,000–80,000 psi.

• Yield strength: ~36,000 psi

2. Manufacturing Process:

• DOM Steel:

• The cold-drawing process eliminates weld seams and enhances dimensional accuracy, strength, and surface finish.

• Used for precision applications like hydraulic cylinders and automotive parts.

• HRPO A36 Steel:

• A low-carbon steel that is hot-rolled, meaning it is less precise in dimensions and has a rougher finish. The pickling and oiling process improves surface quality but does not increase strength.

3. Applications:

• DOM Steel:

• Ideal for high-strength applications requiring precision, such as automotive components, roll cages, and pressure vessels.

• HRPO A36 Steel:

• Commonly used for structural purposes like beams, brackets, and general construction due to its weldability and ductility.

Conclusion:

• DOM steel is stronger, more precise, and better suited for demanding mechanical applications.

• HRPO A36 steel is more affordable and versatile for structural or general-purpose applications where extreme strength isn’t critical.

GP Factor uses HRPO steel

ChatGPT says: DOM (Drawn Over Mandrel) steel is generally stronger than HRPO (Hot Rolled Pickled and Oiled) A36 carbon steel, though the comparison depends on the specific application and properties being evaluated. Here’s why:

Key Differences Between DOM Steel and HRPO A36:

1. Material Strength:

• DOM Steel:

• Typically made from 1018 or 1026 carbon steel, which have higher tensile and yield strengths compared to A36

• The cold-drawing process increases strength, hardness, and uniformity

• Tensile strength: ~70,000–80,000 psi (depending on the grade).

• Yield strength: ~60,000–70,000 psi.

• HRPO A36 Steel:

• A36 is a structural steel with lower strength and is designed for applications where toughness and weldability are prioritized.

• Tensile strength: ~58,000–80,000 psi.

• Yield strength: ~36,000 psi

2. Manufacturing Process:

• DOM Steel:

• The cold-drawing process eliminates weld seams and enhances dimensional accuracy, strength, and surface finish.

• Used for precision applications like hydraulic cylinders and automotive parts.

• HRPO A36 Steel:

• A low-carbon steel that is hot-rolled, meaning it is less precise in dimensions and has a rougher finish. The pickling and oiling process improves surface quality but does not increase strength.

3. Applications:

• DOM Steel:

• Ideal for high-strength applications requiring precision, such as automotive components, roll cages, and pressure vessels.

• HRPO A36 Steel:

• Commonly used for structural purposes like beams, brackets, and general construction due to its weldability and ductility.

Conclusion:

• DOM steel is stronger, more precise, and better suited for demanding mechanical applications.

• HRPO A36 steel is more affordable and versatile for structural or general-purpose applications where extreme strength isn’t critical.

OEM Bull Bar uses Q325

Comparing Q325 steel and DOM (Drawn Over Mandrel) steel involves looking at their properties, manufacturing processes, and typical applications. Here’s a breakdown:

Q325 Steel

1. What is Q325 Steel?

• Q325 is a structural steel grade commonly used in construction and engineering. The “Q” typically refers to “Quenching,” indicating that the material has been processed to improve strength and toughness.

• It is part of the Chinese GB standard system for structural steels.

2. Key Properties:

• Strength: Good tensile and yield strength, suitable for load-bearing applications.

• Toughness: Designed to perform under moderate stress and resist deformation.

• Applications: Commonly used in construction (e.g., bridges, buildings) and general structural components.

3. Pros:

• Cost-effective.

• Adequate for general structural purposes.

• Good weldability and machinability.

4. Cons:

• Limited precision (not designed for high-tolerance applications).

• Surface finish and consistency may not be as refined as DOM steel.

Comparison Table

Property Q325 Steel DOM Steel

Strength Moderate High

Tensile Strength ~450–550 MPa ~450–800 MPa (depending on grade)

Yield Strength ~325 MPa ~350–600 MPa (depending on grade)

Precision Standard structural tolerances Tight tolerances (ideal for machining)

Corrosion Resistance Moderate (depends on treatment) Similar (depends on coating)

Cost Cost-effective More expensive

Applications Construction, load-bearing Automotive, hydraulics, machinery

Comparing Q325 steel and DOM (Drawn Over Mandrel) steel involves looking at their properties, manufacturing processes, and typical applications. Here’s a breakdown:

Q325 Steel

1. What is Q325 Steel?

• Q325 is a structural steel grade commonly used in construction and engineering. The “Q” typically refers to “Quenching,” indicating that the material has been processed to improve strength and toughness.

• It is part of the Chinese GB standard system for structural steels.

2. Key Properties:

• Strength: Good tensile and yield strength, suitable for load-bearing applications.

• Toughness: Designed to perform under moderate stress and resist deformation.

• Applications: Commonly used in construction (e.g., bridges, buildings) and general structural components.

3. Pros:

• Cost-effective.

• Adequate for general structural purposes.

• Good weldability and machinability.

4. Cons:

• Limited precision (not designed for high-tolerance applications).

• Surface finish and consistency may not be as refined as DOM steel.

Comparison Table

Property Q325 Steel DOM Steel

Strength Moderate High

Tensile Strength ~450–550 MPa ~450–800 MPa (depending on grade)

Yield Strength ~325 MPa ~350–600 MPa (depending on grade)

Precision Standard structural tolerances Tight tolerances (ideal for machining)

Corrosion Resistance Moderate (depends on treatment) Similar (depends on coating)

Cost Cost-effective More expensive

Applications Construction, load-bearing Automotive, hydraulics, machinery

I haven’t purchased yet because I’m still in research phase. But …

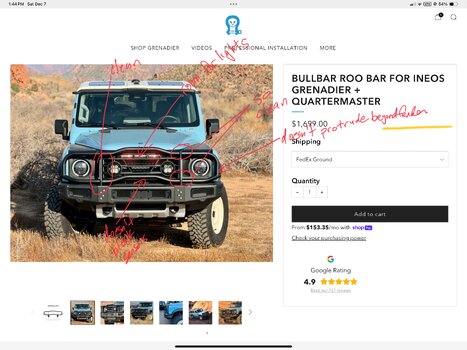

Owl has certainly placed quality and function at the top of their priority list. I like the solid steel risers being narrow so as to not impede air flow and the tubing appears to flow in a manner that doesn’t block any factory lighting nor does it protrude beyond the edges of the vehicle on the side or top. By following the hood and fender contours, they have ensured a clean sight line from the driver’s seat (the sight line being a major advantage of the IG). See pics below for some opinions.

Owl has certainly placed quality and function at the top of their priority list. I like the solid steel risers being narrow so as to not impede air flow and the tubing appears to flow in a manner that doesn’t block any factory lighting nor does it protrude beyond the edges of the vehicle on the side or top. By following the hood and fender contours, they have ensured a clean sight line from the driver’s seat (the sight line being a major advantage of the IG). See pics below for some opinions.

Attachments

The whole point of a brush bar is to protect the body from scratches, so a little protrusion is preferable. The sight line is negligible. airflow is zero issue with any of these. The fatter upright section provides lateral stiffness. In this application you won't notice the steel type used. At these prices all of these become bling so whichever one floats your boat, buy it.

Good Data for sure. Thanks for sharing!Owl uses DOM steel

GP Factor uses HRPO steel

ChatGPT says: DOM (Drawn Over Mandrel) steel is generally stronger than HRPO (Hot Rolled Pickled and Oiled) A36 carbon steel, though the comparison depends on the specific application and properties being evaluated. Here’s why:

Key Differences Between DOM Steel and HRPO A36:

1. Material Strength:

• DOM Steel:

• Typically made from 1018 or 1026 carbon steel, which have higher tensile and yield strengths compared to A36

• The cold-drawing process increases strength, hardness, and uniformity

• Tensile strength: ~70,000–80,000 psi (depending on the grade).

• Yield strength: ~60,000–70,000 psi.

• HRPO A36 Steel:

• A36 is a structural steel with lower strength and is designed for applications where toughness and weldability are prioritized.

• Tensile strength: ~58,000–80,000 psi.

• Yield strength: ~36,000 psi

2. Manufacturing Process:

• DOM Steel:

• The cold-drawing process eliminates weld seams and enhances dimensional accuracy, strength, and surface finish.

• Used for precision applications like hydraulic cylinders and automotive parts.

• HRPO A36 Steel:

• A low-carbon steel that is hot-rolled, meaning it is less precise in dimensions and has a rougher finish. The pickling and oiling process improves surface quality but does not increase strength.

3. Applications:

• DOM Steel:

• Ideal for high-strength applications requiring precision, such as automotive components, roll cages, and pressure vessels.

• HRPO A36 Steel:

• Commonly used for structural purposes like beams, brackets, and general construction due to its weldability and ductility.

Conclusion:

• DOM steel is stronger, more precise, and better suited for demanding mechanical applications.

• HRPO A36 steel is more affordable and versatile for structural or general-purpose applications where extreme strength isn’t critical.

Just for a little clarification, DOM is for tubing, so whatever non tube parts are in anyone's bull bar are not DOM. Those parts are most likely made from CR, HR or HRPO steel (Steel rolls turned into sheets, laser cut and formed). The sheet metal we use is prime HRPO steel. Prime steel is typically held to a tolerance that most would not be able to tell the difference without a micrometer on the thickness. meaning when we order 3/16" steel for the bull bar, all the parts are consistently .1875 thickness (there can be applications where we can have it be closer to .1775 or .1979 depending on wha we are making). For a bull bar, prime steel, whether it be HR, HRPO, or CR are all good choices. The application of bending (forming) parts comes to mind when choosing cold rolled steel. Internal stress can be a factor to consider when choosing cold rolled steel. Most parts in the auto market made from sheet metal are made from HR steel. (excluding stainless and non ferrous metals(Alum, copper, tin, titanium, etc)

We use the pickled and oiled with the material we chose mainly because its easier to work with prior to coating for welding due to no scaling and smoother surface. I am pulling the full chem specs on the tubing we are using and the sheet metal so we can share it with you guys. ill post an update as soon as I have the Chems on the material from the mill.

The "I-beam" style pillar we chose was not only for how it looks but structural strength, like an I-beam as well. The multi sections bolting together at the pillar stack 3 pieces of 3/16 steel (Totaling over a 1/2" of steel support) inside the I-beam of the pillar providing added strength to the pillar and support of the pipes. Minus the tubing, which is 1.9" OD tubing with .125 wall thickness, all of the the sheet metal on the bull bar is made from 3/16 steel.

Last edited:

Sort of… without any welding or an an array of fasteners (bolts/rivets) holding the hoop sections to the center section, forces on the hoops are only going to be transmitted to 3/16 they are welded to. It’ll behave like tearing a phone book. I’m not suggesting that 9/16 of thickness is needed for this to be a nice product, in fact this is clearly the superior overall design, I’m just saying this isn’t the same as using a piece of 1/2 plate.Good Data for sure. Thanks for sharing!

The "I-beam" style pillar we chose was not only for how it looks but structural strength, like an I-beam as well. The multi sections bolting together at the pillar stack 3 pieces of 3/16 steel (Totaling over a 1/2" of steel support) inside the I-beam of the pillar providing added strength to the pillar and support of the pipes.

Above, you replied that the whole purpose of a “brush guard” is to keep your rig from getting scratched. If it’s just for brush, the 3/16 steel will be more than adequate. Where I off road, I’m far less concerned about brush and much more focused on protecting the rig from being disabled in the backcountry by big game … which is why I’m looking for a Bull Bar.Sort of… without any welding or an an array of fasteners (bolts/rivets) holding the hoop sections to the center section, forces on the hoops are only going to be transmitted to 3/16 they are welded to. It’ll behave like tearing a phone book. I’m not suggesting that 9/16 of thickness is needed for this to be a nice product, in fact this is clearly the superior overall design, I’m just saying this isn’t the same as using a piece of 1/2 plate

Well, good luck with any of these hitting elk or moose at 30mph. I notice none of them direct the corpse down like a bull bar, and the taller the animal, the more it flips up and over. And you still have the stock sheet metal bumper. Your whole front clip is being replaced with or without these. Keep in mind, how wide these appear depends entirely on the lens and distance for the camera angle. Sounds like you need an entire steel bumper assembly.Above, you replied that the whole purpose of a “brush guard” is to keep your rig from getting scratched. If it’s just for brush, the 3/16 steel will be more than adequate. Where I off road, I’m far less concerned about brush and much more focused on protecting the rig from being disabled in the backcountry by big game … which is why I’m looking for a Bull Bar.

I went for a steel called HFS, actually it is HFS-B. 'Hell for Stout - Black', it is rated to repel deer, the occasional Prius, and gives me a +2 rating with soccer moms. (although my Wife takes issue with that last part). I don't have to worry about elk or moose down here. Most importantly and without shame, it looks damn cool, its unique, its made in Texas, and makes me happy.

Similar threads

- Replies

- 8

- Views

- 239

- Replies

- 6

- Views

- 1K

- Replies

- 2

- Views

- 321

- Replies

- 11

- Views

- 273