The Grenadier Forum

Register a free account today to become a member! Once signed in, you'll be able to contribute to the community by adding your own topics, posts, and connect with other members through your own private inbox! INEOS Agents, Dealers or Commercial vendors please contact admin@theineosforum.com for a commercial account.

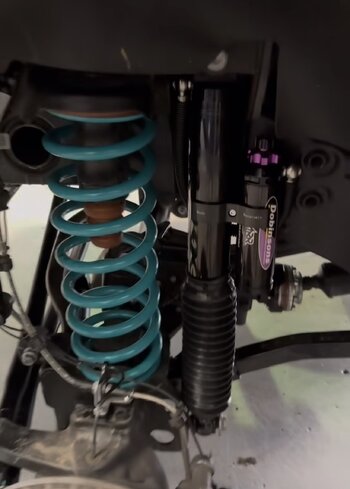

Dobinson 2" Spring lift with Remote Res Shocks and front Winch bar Spotted

Wow, would like to see more photo!

We use Dobinson's heavy duty coils and leaves in fleet vehicles, they make a good product. Their springs generally out last the other brands in the high constant load work vehicles.Interesting update 2" Dobinson's Springs and remote res shocks spotted on the DMW Grenadier

Good to know. I've got their springs and shocks on our hybrid caravan.We use Dobinson's heavy duty coils and leaves in fleet vehicles, they make a good product. Their springs generally out last the other brands in the high constant load work vehicles.

I have many friends among the Landcruiser community who also run Dobbinsons. They seem to hold up well and considering most 80 series Cruisers are in the same weight range as the Gren, they are a good match

I've run Dobinsons springs and shocks on a few vehicles and rated them. Last was on my recently sold 200. No remote reservoir though - I don't need the fancy stuff. Pretty teal and purple though - keeps the carpark fans happy.

Much better than ARB gear, but not as good as say Kings, but also nowhere near the price, and I don't do the Finke or Paris Dakar rallies so all good.

Much better than ARB gear, but not as good as say Kings, but also nowhere near the price, and I don't do the Finke or Paris Dakar rallies so all good.

Is anyone going to address the control angle thus the caster? What about sway bar links? Also in looking at the front drive shaft at full drop on a lift, it was close to maxing out the joint. Longer shock might put that angle into the danger zone.

caster angle is wont be to hard to set. That being said, once taller springs and shocks are installed you’ll need some aftermarket control arms. I’m sure someone will make them before long. Drive shafts and even double CG shafts are pretty easy to have custom made aftermarket. Last I heard Ineos was looking at the possibility of a larger lift with all these options turnkey from the factory.

Prophetic -Is anyone going to address the control angle thus the caster? What about sway bar links? Also in looking at the front drive shaft at full drop on a lift, it was close to maxing out the joint. Longer shock might put that angle into the danger zone.

View: https://www.instagram.com/reel/DB-C9MWy3cC/

The front driveshaft angle is going to be a problem when you lift the truck at all. At this point the best option available seems to be a DC driveshaft but I want someone else to get 10,000 miles on one before I give it a try.

There are several variants of DC style driveshafts discussed in multiple threads here on the forum and all of them suffer from vibration issues. The most promising one was double double cardan, meaning it had a double cardan on each end which is required given the pinion angle cannot be adjusted enough (caster would be reduced to zero or even made negative) to line up a single cardan joint on the pinion end. And even this double double shaft has vibration issues. There is a reason a CV style shaft is the OEM specification. The only true solution will be for Ineos to raise the angle of the differential output in relation to the king ping steering axis. This would preserve the caster, it could even be increased, while reducing the angle of the CV joints on the front shaft. Of course one could cut off the ends of the axle, rotate them and weld them back on but that will be a bridge too far for all but a very small fraction of Grenadier owners.

Last edited:

There are several variants of DC style driveshafts discussed in multiple threads here on the forum and all of them suffer from vibration issues. The most promising one was double double cardan, meaning it had a double cardan on each end which is required given the pinion angle cannot be adjusted enough (caster would be reduced to zero or even made negative) to line up a single cardan joint on the pinion end. And even this double double shaft has vibration issues. There is a reason a CV style shaft is the OEM specification. The only true solution will be for Ineos to raise the angle of the differential output in relation to the king ping steering axis. This would preserve the caster or even improve it while reducing the angle of the CV joints on the front shaft. Of course one could cut off the ends of the axle, rotate them and weld them back on but that will be a bridge too far for all but a very small fraction of Grenadier owners.

Cut and turn the front axle is “common” on Jeeps and old Broncos. Perhaps there will be a day when someone offers a cut and turn exchange service for Grenny front axles.

Hate to see folks learn the expensive way that tall lifts on an otherwise stock Grenny can end in CV and Diff issues. Better to understand the limitations of the stock suspension geometry before making changes which can put stress on the driveline. Modified axles would be about the best solution but most folks aren’t going to go that route as they’ll end up being sold on swanky adjustable arms, links, caster bracket kits, etc… which will end up compromising the suspension dynamics, handling and how the vehicle performs overall. Not saying modifications can’t be done but be prepared for the compromises and in some cases the reduced durability/safety some changes can have.

The eventual solution is a cut an turn, and a better cv joint or dc at the tcase. The double dc joint driveshaft assemblies I'm seeing are still putting a patch on the issue. I guess the big deal is, no one is getting a used axle housing for 500 bucks, and disassembly/reassembly with these wonky axles isn't as straight forward as a Toyo or Dana, and I haven't heard of anyone doing that yet. I know I'm not gonna be beta guy.Hate to see folks learn the expensive way that tall lifts on an otherwise stock Grenny can end in CV and Diff issues. Better to understand the limitations of the stock suspension geometry before making changes which can put stress on the driveline. Modified axles would be about the best solution but most folks aren’t going to go that route as they’ll end up being sold on swanky adjustable arms, links, caster bracket kits, etc… which will end up compromising the suspension dynamics, handling and how the vehicle performs overall. Not saying modifications can’t be done but be prepared for the compromises and in some cases the reduced durability/safety some changes can have.

Agreed. That is why I see some sort of exchange service. They send you a already cut and turned axle and you send them yours. With the proper jigs and processes the surgery wouldn't be very hard. There just might not ever be enough demand for someone to undertake the project.The eventual solution is a cut an turn, and a better cv joint or dc at the tcase. The double dc joint driveshaft assemblies I'm seeing are still putting a patch on the issue. I guess the big deal is, no one is getting a used axle housing for 500 bucks, and disassembly/reassembly with these wonky axles isn't as straight forward as a Toyo or Dana, and I haven't heard of anyone doing that yet. I know I'm not gonna be beta guy.

I think we'd be lucky if someone like Proffitt's land cruisers in Co, would do it, period. Hell, some people would do it without a big lift just to properly dial in a couple degree more camber.Agreed. That is why I see some sort of exchange service. They send you a already cut and turned axle and you send them yours. With the proper jigs and processes the surgery wouldn't be very hard. There just might not ever be enough demand for someone to undertake the project.

Similar threads

- Replies

- 23

- Views

- 1K

- Replies

- 7

- Views

- 2K