While I waited 2 years to receive my Grenadier, I noticed that every single review I saw mentioned how the BMW shift lever just doesn't look like it fits in the cockpit of this off-road vehicle.

To me it looks like a potato. Or maybe a yam.

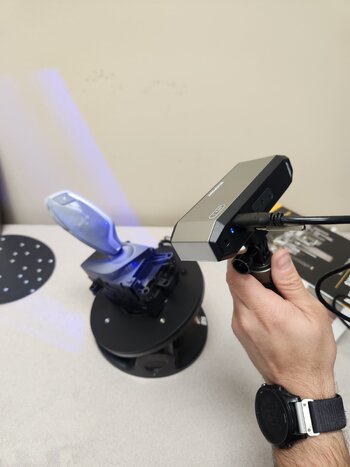

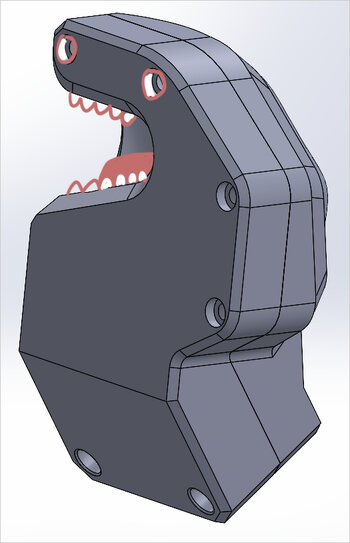

Notable forum member @Tazzieman found a way to improve it:

In March 2023 @trobex started a thread (link below) about the possibility of replacing the shifter, and many wondered aloud why it wasn't a custom design by Ineos to begin with.

https://www.theineosforum.com/threads/gear-shifter-aftermarket-options.12411627/

Why Ineos used a BMW shifter

I wasn't there and I don't know. But as a product design engineer I can imagine some valid reasons why the decision might have been made, and I am confident that it's not as simple as Ineos being cheap. In fact I dare say this was a shrewd engineering decision.

The shift lever is an input device that controls the drivetrain of the vehicle, and as such is a critical component. It is also fairly complex in that it provides multiple inputs, multiple status displays, and even a mechanical motion lockout (the lateral move to the Manual position is mechanically blocked when not allowed). Buyers expect it to keep working even if they are rough with it, spill coffee in it, get sand in it, bathe it in hand lotion, etc. If the lever stops working properly, predictable operation of the vehicle is compromised. This makes the lever a safety-critical component. Getting this device approved and validated is no small feat.

The Grenadier is a low-volume vehicle, in the world of global vehicles. Ineos will do well to make 25,000 Grenadiers this year. BMW makes about 2.5 Million cars/SUVs per year, and a number of the models share shifters. You read that right; BMW will make 100 vehicles for every one Grenadier built this year. BMW can recover engineering and tooling investment across hundreds of thousands of cars over the life of a shifter design. Ineos can not justify paying for this type of complex product development. Notice that all of the complex subassemblies in the Grenadier (engine, trans, xfer case, axles, seats...) are sourced from some company that makes lots and lots of them for other carmakers. It's the only sound strategy if they want to survive.

So I can forgive Ineos the transgression of putting this BMW shift lever in my car.

But I don't plan to leave it that way.

To me it looks like a potato. Or maybe a yam.

Notable forum member @Tazzieman found a way to improve it:

In March 2023 @trobex started a thread (link below) about the possibility of replacing the shifter, and many wondered aloud why it wasn't a custom design by Ineos to begin with.

https://www.theineosforum.com/threads/gear-shifter-aftermarket-options.12411627/

Why Ineos used a BMW shifter

I wasn't there and I don't know. But as a product design engineer I can imagine some valid reasons why the decision might have been made, and I am confident that it's not as simple as Ineos being cheap. In fact I dare say this was a shrewd engineering decision.

The shift lever is an input device that controls the drivetrain of the vehicle, and as such is a critical component. It is also fairly complex in that it provides multiple inputs, multiple status displays, and even a mechanical motion lockout (the lateral move to the Manual position is mechanically blocked when not allowed). Buyers expect it to keep working even if they are rough with it, spill coffee in it, get sand in it, bathe it in hand lotion, etc. If the lever stops working properly, predictable operation of the vehicle is compromised. This makes the lever a safety-critical component. Getting this device approved and validated is no small feat.

The Grenadier is a low-volume vehicle, in the world of global vehicles. Ineos will do well to make 25,000 Grenadiers this year. BMW makes about 2.5 Million cars/SUVs per year, and a number of the models share shifters. You read that right; BMW will make 100 vehicles for every one Grenadier built this year. BMW can recover engineering and tooling investment across hundreds of thousands of cars over the life of a shifter design. Ineos can not justify paying for this type of complex product development. Notice that all of the complex subassemblies in the Grenadier (engine, trans, xfer case, axles, seats...) are sourced from some company that makes lots and lots of them for other carmakers. It's the only sound strategy if they want to survive.

So I can forgive Ineos the transgression of putting this BMW shift lever in my car.

But I don't plan to leave it that way.