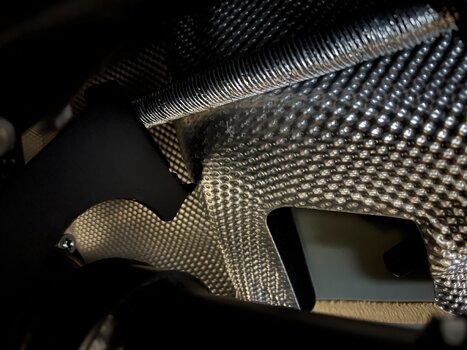

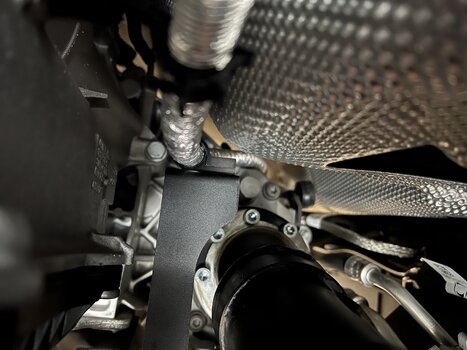

I’m running into some issues fitting the Agile Offroad shift cable retention bracket. There must be some variability between build dates as the bracket does not fit into place and actually interferes with the heat shielding in the transmission tunnel. I’ve had to bend the bracket at a couple of different angles to create some clearance but there is no way the shift cable is going to sit in the cradle as designed on my vehicle. In fact, the cable only seems to fit on the opposite side away from the cradle where it is supposed to be zip tied in.

The shift cable can’t simultaneously bend around the edge of the head shielding and back up to run through the bracket support there isn’t enough clearance on the cradle side. My build has the aluminum shielding around the cable making it more difficult to manipulate or reposition. The only solution I can think of is to use an aluminum P-Clamp and turn it around so the cable is supported on the non-cradle side of the bracket.

I’ll most likely have to cut the cradle end off of the bracket at the point where the slot is for the zip tie in order to make sure the bracket doesn’t interfere with the shielding and allows for some small relative movement between the chassis mounted bracket and body mounted shift cable. It’s a bit of a DIY fix but certainly didn’t plan on it being this much of a hassle.

The shift cable can’t simultaneously bend around the edge of the head shielding and back up to run through the bracket support there isn’t enough clearance on the cradle side. My build has the aluminum shielding around the cable making it more difficult to manipulate or reposition. The only solution I can think of is to use an aluminum P-Clamp and turn it around so the cable is supported on the non-cradle side of the bracket.

I’ll most likely have to cut the cradle end off of the bracket at the point where the slot is for the zip tie in order to make sure the bracket doesn’t interfere with the shielding and allows for some small relative movement between the chassis mounted bracket and body mounted shift cable. It’s a bit of a DIY fix but certainly didn’t plan on it being this much of a hassle.