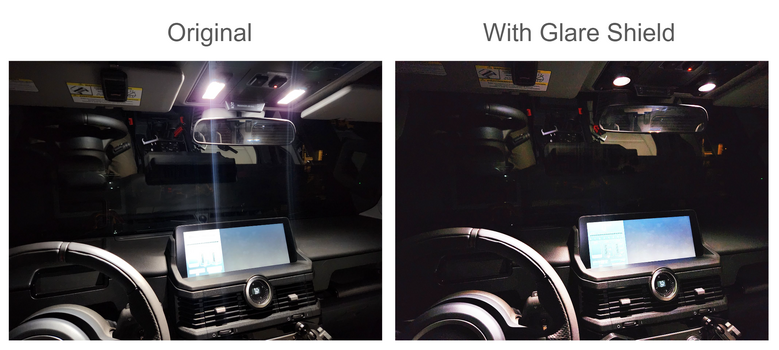

I appreciate good lighting, and have been unimpressed by the harsh glare from the front seat map lights positioned just above the rearview mirror in the Grenadier. They are molded into a transparent lens housing that scatters light in every direction, including into the driver's eyes.

This pair of 3D-printable glare shields is easy to attach using the existing cosmetic socket head cap screws near the front seat map lights. Different LH and RH shields are required to account for the panel layout around the two lights. This modification allows a passenger to safely use their map light with minimal impact to the driver's night vision. It also just makes the front seat lighting more pleasant in general.

Adding these does not require removing anything but 2x (per side) cosmetic screws from the original overhead console panel. These socket-head cap screws can be re-used to retain the shield, but the resulting thread engagement is limited. Ideally, longer screws would be sourced. I re-used the original screws but have been careful not to over-tighten. It has been fine.

Virtually any 3d-printed material should work fine for this. The printed part in the pics is a FDM from a Markforged printer using Onyx filament with a 0.1mm print layer height.

This was modeled in SolidWorks 2023. DM me for the source file if you want to modify this design.

This pair of 3D-printable glare shields is easy to attach using the existing cosmetic socket head cap screws near the front seat map lights. Different LH and RH shields are required to account for the panel layout around the two lights. This modification allows a passenger to safely use their map light with minimal impact to the driver's night vision. It also just makes the front seat lighting more pleasant in general.

Adding these does not require removing anything but 2x (per side) cosmetic screws from the original overhead console panel. These socket-head cap screws can be re-used to retain the shield, but the resulting thread engagement is limited. Ideally, longer screws would be sourced. I re-used the original screws but have been careful not to over-tighten. It has been fine.

Virtually any 3d-printed material should work fine for this. The printed part in the pics is a FDM from a Markforged printer using Onyx filament with a 0.1mm print layer height.

This was modeled in SolidWorks 2023. DM me for the source file if you want to modify this design.