FWIW: Perhaps the "off road" is designed to reduce the risk of oil starvation in "extreme lean" (>25deg) events rather than off road/ overlanding trips where lesser gradients might be experienced.

The Grenadier Forum

Register a free account today to become a member! Once signed in, you'll be able to contribute to the community by adding your own topics, posts, and connect with other members through your own private inbox! INEOS Agents, Dealers or Commercial vendors please use the contact us link at the bottom of the page.

-

Guest submit your best shot for a chance to win the December Photo Contest. Photo Contest Click Here

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Motor oil change instructions and parts?

If not ok then it tells you to refill. In my case refill 500ml for off-road. Ive stuck in 700ml and it still shows on road ok and off road fill 500ml.Also, unless I am doing it wrong,

all I get when checking oil level is that it is 'OK'

Have not found any indication of the actual level / how much to add. Assume it will wait until the level is not 'OK' but still need to know how much to add at that pont.

Give me a simple dipstick that is accessible and reliable. Computers may work 60pct of the time everytime but a dipstick works bloody 100pct!

I am presuming that when it needs 500ml it will say add 500ml. Until then the only word in its vocabulary is "OK"Also, unless I am doing it wrong,

all I get when checking oil level is that it is 'OK'

Have not found any indication of the actual level / how much to add. Assume it will wait until the level is not 'OK' but still need to know how much to add at that pont.

It doesn't know if it's Arthur or Martha.If not ok then it tells you to refill. In my case refill 500ml for off-road. Ive stuck in 700ml and it still shows on road ok and off road fill 500ml.

Give me a simple dipstick that is accessible and reliable. Computers may work 60pct of the time everytime but a dipstick works bloody 100pct!

I'm not sure which way to turn.

Will it say overfull if you drop 2L in?

I have little confidence in it. I chucked in 5l from a container and then measured out a further 2.5l, ran it, said needed 500ml off road, stuck in 500ml and still said needed another 500ml. Will leave it alone until change again in Sept.It doesn't know if it's Arthur or Martha.

I'm not sure which way to turn.

Will it say overfull if you drop 2L in?

On collecting after getting gren home for first time I ran the oil test and it said 500ml off road required.

I saved this from somewhere ; maybe someone here a while ago.

See the comment re condensates and short trips.

"The electrical material properties of the engine oil change as the engine oil wears and ages. The changed electrical properties of the engine oil (dielectrics) cause the capacity of the capacitor to change.

The electronic evaluation unit converts the measured capacity into a digital signal. The digital sensor signal is sent to the engine management system. The engine management system uses the signal for internal calculations"

How the oil condition sensor works. In summary, it measures the conductivity of the oil. as the oil moves from base to acid, and contaminants collect in the oil, the oil becomes more conductive. The oil condition sensors monitors the change, and indicates the oil needs changed when the contaminants and acidity reach a certain threshold.

From the BMW System functions

The following system functions are described for the oil condition sensor:

! Measuring method

! Electronic oil level control

Measuring method

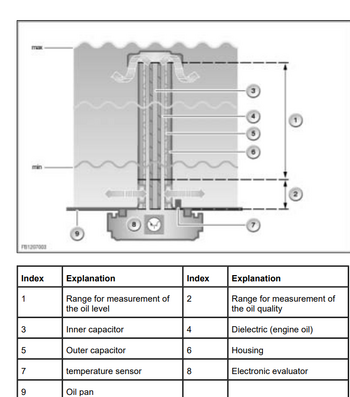

The oil condition sensor consists of 2 cylindrical condensers. The condensers are mounted above one another. 2 metal tubes are inserted one into the other to serve as electrodes. The engine oil is used as a dielectric medium between the electrodes.

Note! Explanation of the terms 'dielectric' and 'permittivity'.

A dielectric is defined as a non-conductive material in an electrical field. The electrical field is split by an insulator.

The permittivity (Latin: permittere = permit, let through) is also referred to as the dielectric conductance. The permittivity specifies the degree to which materials allow electrical fields to pass.

The factor indicates by how much the voltage at a capacitor drops when a dielectric, non-conducting material.

The temperature sensor is seated on the housing of the oil condition sensor. The housing of the oil condition sensor contains an electronic evaluation unit. The electronic evaluation unit has self-diagnosis. A fault in the oil condition sensor is entered in the fault memory of the engine management system.

The oil condition sensor sends its measured values to the engine management system:

! Engine oil temperature

! Oil level

! Engine oil quality

The electrical material properties of the engine oil change as the engine oil wears and ages. The changed electrical properties of the engine oil (dielectrics) cause the capacity of the capacitor to change. The electronic evaluation unit converts the measured capacity into a digital signal. The digital sensor signal is sent to the engine management system. The engine management system uses the signal for internal calculations (e.g. condensate in the engine oil).

Note: condensate in the engine oil.

Condensate that forms in the crankcase due to short distance driving can influence the permittivity. If the water is mixed in the engine oil, it also collects around the oil condition sensor.

If there is too much water in the crankcase:

In individual cases there can be an incorrect display of the oil level or a warning requesting that the oil be topped up.

This "false oil level warning" can be treated by means of a fault profile selection on the BMW diagnosis system, whereby the permittivity of the oil is also evaluated. However, there is no direct display of the permittivity. The permittivity depends on, among other things, the viscosity or age of the oil. This means that an appraisal of the quality is not ensured in every case. "

See the comment re condensates and short trips.

"The electrical material properties of the engine oil change as the engine oil wears and ages. The changed electrical properties of the engine oil (dielectrics) cause the capacity of the capacitor to change.

The electronic evaluation unit converts the measured capacity into a digital signal. The digital sensor signal is sent to the engine management system. The engine management system uses the signal for internal calculations"

How the oil condition sensor works. In summary, it measures the conductivity of the oil. as the oil moves from base to acid, and contaminants collect in the oil, the oil becomes more conductive. The oil condition sensors monitors the change, and indicates the oil needs changed when the contaminants and acidity reach a certain threshold.

From the BMW System functions

The following system functions are described for the oil condition sensor:

! Measuring method

! Electronic oil level control

Measuring method

The oil condition sensor consists of 2 cylindrical condensers. The condensers are mounted above one another. 2 metal tubes are inserted one into the other to serve as electrodes. The engine oil is used as a dielectric medium between the electrodes.

Note! Explanation of the terms 'dielectric' and 'permittivity'.

A dielectric is defined as a non-conductive material in an electrical field. The electrical field is split by an insulator.

The permittivity (Latin: permittere = permit, let through) is also referred to as the dielectric conductance. The permittivity specifies the degree to which materials allow electrical fields to pass.

The factor indicates by how much the voltage at a capacitor drops when a dielectric, non-conducting material.

The temperature sensor is seated on the housing of the oil condition sensor. The housing of the oil condition sensor contains an electronic evaluation unit. The electronic evaluation unit has self-diagnosis. A fault in the oil condition sensor is entered in the fault memory of the engine management system.

The oil condition sensor sends its measured values to the engine management system:

! Engine oil temperature

! Oil level

! Engine oil quality

The electrical material properties of the engine oil change as the engine oil wears and ages. The changed electrical properties of the engine oil (dielectrics) cause the capacity of the capacitor to change. The electronic evaluation unit converts the measured capacity into a digital signal. The digital sensor signal is sent to the engine management system. The engine management system uses the signal for internal calculations (e.g. condensate in the engine oil).

Note: condensate in the engine oil.

Condensate that forms in the crankcase due to short distance driving can influence the permittivity. If the water is mixed in the engine oil, it also collects around the oil condition sensor.

If there is too much water in the crankcase:

In individual cases there can be an incorrect display of the oil level or a warning requesting that the oil be topped up.

This "false oil level warning" can be treated by means of a fault profile selection on the BMW diagnosis system, whereby the permittivity of the oil is also evaluated. However, there is no direct display of the permittivity. The permittivity depends on, among other things, the viscosity or age of the oil. This means that an appraisal of the quality is not ensured in every case. "

Did my oil change on Wednesday. We added 7qts and did the check procedure, waiting until the vehicle was up to temp. It indicated a qt low, so we added a qt and then checked again, system reported O for bot on and off road..Also, unless I am doing it wrong,

all I get when checking oil level is that it is 'OK'

Have not found any indication of the actual level / how much to add. Assume it will wait until the level is not 'OK' but still need to know how much to add at that pont.

This is in line with what I was told by the Ineos dealer in Idaho, that it wanted 8qts instead of 7.

We used Liquid Moly 6600

Last edited:

So for the rest of us , that's 7.5LThis is in line with what I was told by the Ineos dealer in Idaho, that it wanted 8qts instead of 7.

That's about 1L more than in the B58 engine in the SUVs

I'm curious, do they still sell oil in qts in the US, I thought that it would be branded worldwide in litres?Did my oil change on Wednesday. We added 7qts and did the check procedure, waiting until the vehicle was up to temp. It indicated a qt low, so we added a qt and then checked again, system reported O for bot on and off road..

This is in line with what I was told by the Ineos dealer in Idaho, that it wanted 8qts instead of 7.

We used Liquid Moly 6600

View attachment 7845218

View attachment 7845217

Perhaps you are right - old habits die hard. It was likely 8 litersI'm curious, do they still sell oil in qts in the US, I thought that it would be branded worldwide in litres?

This makes my head hurt. WTF is wrong with just using a dipstick? I get that IA is using BMW engines so modification may not have been available, but in the "build for purpose" mindset, relying on a computer to check the oil seems a bit short sighted.I saved this from somewhere ; maybe someone here a while ago.

See the comment re condensates and short trips.

"The electrical material properties of the engine oil change as the engine oil wears and ages. The changed electrical properties of the engine oil (dielectrics) cause the capacity of the capacitor to change.

The electronic evaluation unit converts the measured capacity into a digital signal. The digital sensor signal is sent to the engine management system. The engine management system uses the signal for internal calculations"

How the oil condition sensor works. In summary, it measures the conductivity of the oil. as the oil moves from base to acid, and contaminants collect in the oil, the oil becomes more conductive. The oil condition sensors monitors the change, and indicates the oil needs changed when the contaminants and acidity reach a certain threshold.

From the BMW System functions

The following system functions are described for the oil condition sensor:

! Measuring method

! Electronic oil level control

Measuring method

The oil condition sensor consists of 2 cylindrical condensers. The condensers are mounted above one another. 2 metal tubes are inserted one into the other to serve as electrodes. The engine oil is used as a dielectric medium between the electrodes.

Note! Explanation of the terms 'dielectric' and 'permittivity'.

A dielectric is defined as a non-conductive material in an electrical field. The electrical field is split by an insulator.

The permittivity (Latin: permittere = permit, let through) is also referred to as the dielectric conductance. The permittivity specifies the degree to which materials allow electrical fields to pass.

The factor indicates by how much the voltage at a capacitor drops when a dielectric, non-conducting material.

The temperature sensor is seated on the housing of the oil condition sensor. The housing of the oil condition sensor contains an electronic evaluation unit. The electronic evaluation unit has self-diagnosis. A fault in the oil condition sensor is entered in the fault memory of the engine management system.

The oil condition sensor sends its measured values to the engine management system:

! Engine oil temperature

! Oil level

! Engine oil quality

The electrical material properties of the engine oil change as the engine oil wears and ages. The changed electrical properties of the engine oil (dielectrics) cause the capacity of the capacitor to change. The electronic evaluation unit converts the measured capacity into a digital signal. The digital sensor signal is sent to the engine management system. The engine management system uses the signal for internal calculations (e.g. condensate in the engine oil).

Note: condensate in the engine oil.

Condensate that forms in the crankcase due to short distance driving can influence the permittivity. If the water is mixed in the engine oil, it also collects around the oil condition sensor.

If there is too much water in the crankcase:

In individual cases there can be an incorrect display of the oil level or a warning requesting that the oil be topped up.

This "false oil level warning" can be treated by means of a fault profile selection on the BMW diagnosis system, whereby the permittivity of the oil is also evaluated. However, there is no direct display of the permittivity. The permittivity depends on, among other things, the viscosity or age of the oil. This means that an appraisal of the quality is not ensured in every case. "

There is a similar explanation and another very detailed operation post in the Bimmerpost forum. For those who like visuals I have added an old BMW diagram from around 2008, old but still relevant. The current sensor is likely to be the result of multiple upgrades and software updates by now. There are various other types of sensors that use ultrasonics, floats, optics and resistance used by other OEMs.I saved this from somewhere ; maybe someone here a while ago.

See the comment re condensates and short trips.

"The electrical material properties of the engine oil change as the engine oil wears and ages. The changed electrical properties of the engine oil (dielectrics) cause the capacity of the capacitor to change.

The electronic evaluation unit converts the measured capacity into a digital signal. The digital sensor signal is sent to the engine management system. The engine management system uses the signal for internal calculations"

How the oil condition sensor works. In summary, it measures the conductivity of the oil. as the oil moves from base to acid, and contaminants collect in the oil, the oil becomes more conductive. The oil condition sensors monitors the change, and indicates the oil needs changed when the contaminants and acidity reach a certain threshold.

From the BMW System functions

The following system functions are described for the oil condition sensor:

! Measuring method

! Electronic oil level control

Measuring method

The oil condition sensor consists of 2 cylindrical condensers. The condensers are mounted above one another. 2 metal tubes are inserted one into the other to serve as electrodes. The engine oil is used as a dielectric medium between the electrodes.

Note! Explanation of the terms 'dielectric' and 'permittivity'.

A dielectric is defined as a non-conductive material in an electrical field. The electrical field is split by an insulator.

The permittivity (Latin: permittere = permit, let through) is also referred to as the dielectric conductance. The permittivity specifies the degree to which materials allow electrical fields to pass.

The factor indicates by how much the voltage at a capacitor drops when a dielectric, non-conducting material.

The temperature sensor is seated on the housing of the oil condition sensor. The housing of the oil condition sensor contains an electronic evaluation unit. The electronic evaluation unit has self-diagnosis. A fault in the oil condition sensor is entered in the fault memory of the engine management system.

The oil condition sensor sends its measured values to the engine management system:

! Engine oil temperature

! Oil level

! Engine oil quality

The electrical material properties of the engine oil change as the engine oil wears and ages. The changed electrical properties of the engine oil (dielectrics) cause the capacity of the capacitor to change. The electronic evaluation unit converts the measured capacity into a digital signal. The digital sensor signal is sent to the engine management system. The engine management system uses the signal for internal calculations (e.g. condensate in the engine oil).

Note: condensate in the engine oil.

Condensate that forms in the crankcase due to short distance driving can influence the permittivity. If the water is mixed in the engine oil, it also collects around the oil condition sensor.

If there is too much water in the crankcase:

In individual cases there can be an incorrect display of the oil level or a warning requesting that the oil be topped up.

This "false oil level warning" can be treated by means of a fault profile selection on the BMW diagnosis system, whereby the permittivity of the oil is also evaluated. However, there is no direct display of the permittivity. The permittivity depends on, among other things, the viscosity or age of the oil. This means that an appraisal of the quality is not ensured in every case. "

Last edited:

I'm going to do my first filter, drain & fill this weekend. Have 9 quarts of oil on hand.

And I can't see anyway to make that doable.I've been using an oil evacuator for most of my cars, so much easier than draining from the bottom, but if there isn't a dipstick tube, it won't work. Silly.

Can't we just have a damm dip stick for the Petrol engine.I saved this from somewhere ; maybe someone here a while ago.

See the comment re condensates and short trips.

"The electrical material properties of the engine oil change as the engine oil wears and ages. The changed electrical properties of the engine oil (dielectrics) cause the capacity of the capacitor to change.

The electronic evaluation unit converts the measured capacity into a digital signal. The digital sensor signal is sent to the engine management system. The engine management system uses the signal for internal calculations"

How the oil condition sensor works. In summary, it measures the conductivity of the oil. as the oil moves from base to acid, and contaminants collect in the oil, the oil becomes more conductive. The oil condition sensors monitors the change, and indicates the oil needs changed when the contaminants and acidity reach a certain threshold.

From the BMW System functions

The following system functions are described for the oil condition sensor:

! Measuring method

! Electronic oil level control

Measuring method

The oil condition sensor consists of 2 cylindrical condensers. The condensers are mounted above one another. 2 metal tubes are inserted one into the other to serve as electrodes. The engine oil is used as a dielectric medium between the electrodes.

Note! Explanation of the terms 'dielectric' and 'permittivity'.

A dielectric is defined as a non-conductive material in an electrical field. The electrical field is split by an insulator.

The permittivity (Latin: permittere = permit, let through) is also referred to as the dielectric conductance. The permittivity specifies the degree to which materials allow electrical fields to pass.

The factor indicates by how much the voltage at a capacitor drops when a dielectric, non-conducting material.

The temperature sensor is seated on the housing of the oil condition sensor. The housing of the oil condition sensor contains an electronic evaluation unit. The electronic evaluation unit has self-diagnosis. A fault in the oil condition sensor is entered in the fault memory of the engine management system.

The oil condition sensor sends its measured values to the engine management system:

! Engine oil temperature

! Oil level

! Engine oil quality

The electrical material properties of the engine oil change as the engine oil wears and ages. The changed electrical properties of the engine oil (dielectrics) cause the capacity of the capacitor to change. The electronic evaluation unit converts the measured capacity into a digital signal. The digital sensor signal is sent to the engine management system. The engine management system uses the signal for internal calculations (e.g. condensate in the engine oil).

Note: condensate in the engine oil.

Condensate that forms in the crankcase due to short distance driving can influence the permittivity. If the water is mixed in the engine oil, it also collects around the oil condition sensor.

If there is too much water in the crankcase:

In individual cases there can be an incorrect display of the oil level or a warning requesting that the oil be topped up.

This "false oil level warning" can be treated by means of a fault profile selection on the BMW diagnosis system, whereby the permittivity of the oil is also evaluated. However, there is no direct display of the permittivity. The permittivity depends on, among other things, the viscosity or age of the oil. This means that an appraisal of the quality is not ensured in every case. "

Someone needs to create a template so we will know exactly where to drill a hole in the engine.

I will the be the first to purchase it.

Sounds like you should be the 1st one to drill a hole!Can't we just have a damm dip stick for the Petrol engine.

Someone needs to create a template so we will know exactly where to drill a hole in the engine.

I will the be the first to purchase it.

DaBull

Let us know how it goes. I'm particularly interested in the ease of removing the old filter and then installing the new one. Also, what condition is the old filter in when you take it out? Coming up on my first oil change (at 800mi) and have been reading a lot about the B58 filter issues. Thanks!I'm going to do my first filter, drain & fill this weekend. Have 9 quarts of oil on hand.

Couldn't agree more Also incorporates something else to break. Why not use the 'KISS' principle?WTF is wrong with just using a dipstick?

Similar threads

- Replies

- 4

- Views

- 554

- Replies

- 40

- Views

- 2K

- Replies

- 15

- Views

- 1K

- Replies

- 6

- Views

- 779

- Replies

- 1

- Views

- 243